Discover the Benefits of High-Quality Wafer Arm Technology

By:Admin

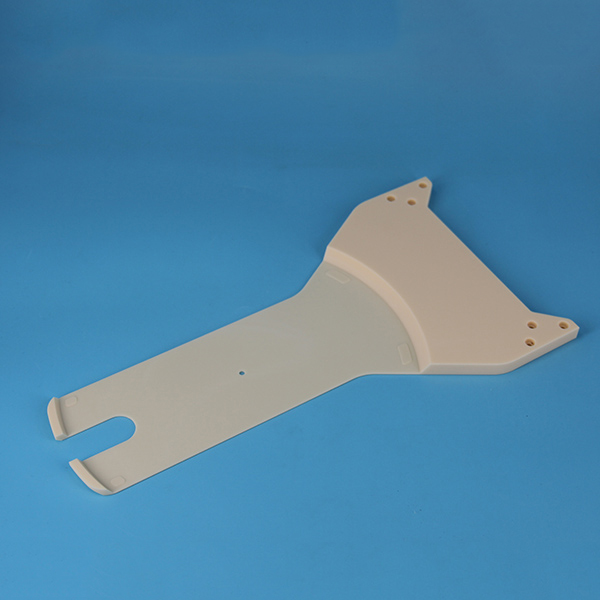

St.Cera Co., Ltd. is a private high-tech enterprise specializing in precision ceramic manufacturing. The company has a team of top-ranking experts and engineers in precision ceramic manufacturing. Our core competencies lie in research and development, manufacturing, and marketing of precision ceramic parts. With a strong commitment to quality and innovation, St.Cera Co., Ltd. has recently introduced a high-quality Wafer Arm, designed to meet the demands of the semiconductor industry.

The Wafer Arm, which has been carefully crafted using advanced ceramic manufacturing techniques, is a crucial component in the production of semiconductors. Its high-quality construction and precision engineering make it an ideal choice for semiconductor manufacturers seeking to enhance the performance and reliability of their production processes.

The Wafer Arm developed by St.Cera Co., Ltd. has been specifically designed to meet the stringent requirements of the semiconductor industry. Made from high-quality ceramic materials, the Wafer Arm offers exceptional dimensional stability, high strength, and excellent wear resistance. These properties make it an ideal choice for handling delicate silicon wafers during the various stages of semiconductor production.

Furthermore, the Wafer Arm is designed to withstand the high temperatures and corrosive environments commonly encountered in semiconductor manufacturing facilities. Its superior thermal stability and resistance to chemical attack ensure that it can maintain its performance and reliability over extended periods of use.

In addition to its exceptional physical properties, the Wafer Arm is also designed with precision and accuracy in mind. Its advanced design and manufacturing processes ensure that it can handle the delicate silicon wafers with the utmost care, minimizing the risk of damage or contamination during production. This level of precision is crucial for semiconductor manufacturers, as even the smallest imperfection or defect can have a significant impact on the performance and reliability of the final semiconductor products.

The introduction of the high-quality Wafer Arm represents a significant milestone for St.Cera Co., Ltd. and demonstrates the company's commitment to meeting the evolving needs of the semiconductor industry. By leveraging its expertise in precision ceramic manufacturing, the company has developed a product that offers superior performance, reliability, and longevity, making it an invaluable asset for semiconductor manufacturers.

Moreover, St.Cera Co., Ltd. has also invested heavily in research and development to ensure that the Wafer Arm remains at the forefront of technological advancements in the semiconductor industry. The company's team of top-ranking experts and engineers are constantly exploring new materials, manufacturing techniques, and design concepts to further enhance the performance and capabilities of the Wafer Arm.

The introduction of the high-quality Wafer Arm has already garnered significant interest from semiconductor manufacturers around the world. Several leading companies have expressed their enthusiasm for the new product, citing its potential to improve the efficiency and reliability of their semiconductor production processes. The exceptional quality and performance of the Wafer Arm have positioned it as a key solution for addressing the evolving challenges and demands of the semiconductor industry.

In conclusion, the introduction of the high-quality Wafer Arm by St.Cera Co., Ltd. represents a significant technological advancement for the semiconductor industry. With its exceptional physical properties, precision engineering, and commitment to quality, the Wafer Arm is poised to become a vital component in the production of semiconductors. As St.Cera Co., Ltd. continues to innovate and push the boundaries of precision ceramic manufacturing, the future looks promising for the Wafer Arm and its potential to revolutionize semiconductor production.

Company News & Blog

High performance boron nitride ceramic rod for various industrial applications

Boron Nitride Ceramic Rod, a Breakthrough in Advanced Engineering The field of advanced engineering and materials science has taken a great leap forward with the introduction of Boron Nitride Ceramic Rod, a revolutionary new product that promises to revolutionize a wide range of industries. Created by a team of expert researchers and engineers at {}, this groundbreaking material offers exceptional thermal conductivity, high temperature and chemical resistance, and outstanding mechanical strength. The innovative properties of Boron Nitride Ceramic Rod make it an ideal choice for applications in aerospace, automotive, electronics, and many other fields.Boron Nitride Ceramic Rod is a high-performance material that is designed to exceed the limitations of traditional materials such as metal, plastic, and other ceramics. It is composed of a unique combination of boron and nitrogen atoms, arranged in a hexagonal lattice structure, which gives the material its exceptional properties. This structure allows Boron Nitride Ceramic Rod to exhibit high thermal conductivity, even at extremely high temperatures, making it an excellent choice for applications in the aerospace and automotive industries. Additionally, the material's resistance to chemicals and corrosion makes it a viable option for use in aggressive environments, and its exceptional mechanical strength allows for a wide range of engineering applications.The properties of Boron Nitride Ceramic Rod are unmatched by any other material currently available on the market, making it an attractive choice for a wide range of industries. With its high thermal conductivity, the material allows for efficient heat transfer, reducing the risk of overheating in electronic devices, automotive engines, and aerospace components. The material's exceptional resistance to chemicals and corrosion makes it an ideal choice for use in aggressive environments, including chemical processing plants and offshore platforms. Additionally, the high mechanical strength of Boron Nitride Ceramic Rod allows for its use in a wide range of engineering applications, including cutting tools, bearings, and high-performance components.Boron Nitride Ceramic Rod is set to revolutionize the way engineers and researchers approach advanced materials and engineering solutions. Its unique combination of properties makes it an attractive choice for a wide range of industries, where traditional materials may fall short. The material's high thermal conductivity, resistance to chemicals and corrosion, and outstanding mechanical strength make it a valuable asset for applications in aerospace, automotive, electronics, and many other fields. With its introduction, engineers and researchers will have a new tool at their disposal to push the boundaries of what is possible in advanced engineering and materials science.The development of Boron Nitride Ceramic Rod is a testament to the dedication and expertise of the team at {}. With years of experience in materials science and engineering, the company has been at the forefront of innovation in advanced materials. Their commitment to pushing the boundaries of what is possible has led to the creation of Boron Nitride Ceramic Rod, a breakthrough material that promises to revolutionize a wide range of industries. The company's dedication to excellence and innovation has positioned them as a leader in the field of advanced engineering and materials science, and with the introduction of Boron Nitride Ceramic Rod, they continue to set the standard for cutting-edge materials and engineering solutions.In conclusion, Boron Nitride Ceramic Rod is an exceptional material that promises to revolutionize a wide range of industries with its unique combination of properties. Its high thermal conductivity, resistance to chemicals and corrosion, and outstanding mechanical strength make it an ideal choice for applications in aerospace, automotive, electronics, and many other fields. With its introduction, engineers and researchers now have a valuable new tool at their disposal to push the boundaries of what is possible in advanced engineering and materials science. The development of Boron Nitride Ceramic Rod is a testament to the dedication and expertise of the team at {}, who continue to set the standard for cutting-edge materials and engineering solutions.

High-Quality Zirconia Ceramics Tube for Various Industrial Applications

St.Cera Co., Ltd., a private high-tech enterprise specializing in precision ceramic manufacturing, has recently announced the release of a new product, the Zirconia Ceramics Tube. This innovative new product is set to revolutionize the industry with its advanced technology and high-quality materials.The Zirconia Ceramics Tube is the result of extensive research and development by St.Cera Co., Ltd.'s team of top-ranking experts and engineers. Zirconia ceramics are known for their excellent mechanical properties, high wear resistance, and outstanding thermal stability, making them ideal for a wide range of applications. With the introduction of the Zirconia Ceramics Tube, St.Cera Co., Ltd. is once again demonstrating its commitment to providing cutting-edge solutions to its customers.The Zirconia Ceramics Tube is a versatile product that can be used in various industries, including medical, aerospace, semiconductor, and precision engineering. Its high wear resistance and exceptional durability make it an ideal choice for applications where reliability and performance are essential. With its superior thermal stability, the Zirconia Ceramics Tube can withstand extreme temperatures, making it suitable for use in challenging environments.In addition to its excellent mechanical properties, the Zirconia Ceramics Tube also offers outstanding corrosion resistance, making it an ideal choice for applications where exposure to harsh chemicals is a concern. Its biocompatibility also makes it suitable for use in medical devices and implants, further expanding its potential applications."The release of the Zirconia Ceramics Tube is a significant milestone for St.Cera Co., Ltd.," said the company's spokesperson. "We are proud to bring this advanced product to the market, and we are confident that it will meet the needs of our customers in a wide range of industries."St.Cera Co., Ltd. is known for its expertise in precision ceramic manufacturing, and the introduction of the Zirconia Ceramics Tube further solidifies its position as a leader in the industry. The company's core competencies in research and development, manufacturing, and marketing of precision ceramic parts have enabled it to consistently deliver innovative solutions that meet the highest standards of quality and reliability.With its strong focus on technology and innovation, St.Cera Co., Ltd. is well-positioned to meet the evolving needs of its customers and maintain its competitive edge in the market. The company's commitment to excellence and dedication to continuous improvement is reflected in the superior quality of its products, including the Zirconia Ceramics Tube.As St.Cera Co., Ltd. continues to expand its presence in the global market, the release of the Zirconia Ceramics Tube underscores its commitment to providing customers with advanced solutions that deliver exceptional performance and value. With its outstanding mechanical properties, high wear resistance, and superior thermal stability, the Zirconia Ceramics Tube is poised to set a new standard for excellence in precision ceramic manufacturing.As the demand for high-performance materials continues to grow across a wide range of industries, the Zirconia Ceramics Tube is expected to play a key role in meeting the needs of manufacturers and engineers who are seeking reliable and durable solutions. Its versatility and exceptional properties make it an ideal choice for applications where precision and performance are essential.With the introduction of the Zirconia Ceramics Tube, St.Cera Co., Ltd. is once again demonstrating its leadership in the field of precision ceramic manufacturing, setting a new benchmark for quality, reliability, and innovation. As the company continues to push the boundaries of what is possible with ceramic materials, the Zirconia Ceramics Tube stands as a testament to its dedication to delivering advanced solutions that meet the needs of its customers in a wide range of industries.

High-Quality Custom Sapphire Dowel Pins for Various Applications

St.Cera Co., Ltd., a private high-tech enterprise specializing in precision ceramic manufacturing, has recently introduced Custom Sapphire Dowel Pins to their extensive line of precision ceramic parts. The company, known for its top-ranking experts and engineers in the field, is excited to offer this new product to their customers.Sapphire is a remarkable material known for its exceptional hardness and resistance to wear, making it an ideal choice for applications requiring high strength and durability. The addition of Custom Sapphire Dowel Pins to St.Cera's product portfolio further solidifies the company's position as a leading provider of high-quality precision ceramic parts.The Custom Sapphire Dowel Pins are manufactured with the utmost precision and attention to detail, ensuring that they meet the exacting standards that St.Cera is known for. These dowel pins are designed to provide superior performance in a wide range of applications, including aerospace, automotive, medical, and industrial equipment.One of the key benefits of Custom Sapphire Dowel Pins is their exceptional hardness, which makes them highly resistant to abrasion and wear. This characteristic ensures that the dowel pins maintain their integrity and performance even in the most demanding environments, offering long-term reliability and longevity.In addition to their superior hardness, Custom Sapphire Dowel Pins also exhibit excellent thermal and chemical resistance. This makes them well-suited for applications where exposure to extreme temperatures and harsh chemicals is a concern, providing a reliable and long-lasting solution for a variety of industries.Furthermore, the precision manufacturing process employed by St.Cera ensures that each Custom Sapphire Dowel Pin meets the exact specifications required by their customers. This level of precision and attention to detail is a hallmark of the company's commitment to delivering high-quality products that meet the needs of their clients.The introduction of Custom Sapphire Dowel Pins further underscores St.Cera's dedication to innovation and continuous improvement. By expanding their product offering to include this innovative material, the company is demonstrating its ability to adapt to the evolving needs of the market and provide cutting-edge solutions to its customers.In addition to Custom Sapphire Dowel Pins, St.Cera offers a wide range of precision ceramic parts, including custom components designed to meet specific requirements. The company's expertise in research and development, manufacturing, and marketing of precision ceramic parts allows them to cater to a diverse range of industries and applications.St.Cera's team of top-ranking experts and engineers plays a pivotal role in the company's success, providing the knowledge and experience necessary to develop and deliver high-quality products to their customers. Their commitment to excellence and relentless pursuit of innovation positions St.Cera as a trusted partner for businesses seeking reliable and high-performance precision ceramic parts.With the introduction of Custom Sapphire Dowel Pins, St.Cera continues to uphold its reputation as a leader in precision ceramic manufacturing. The company's unwavering dedication to quality and customer satisfaction sets them apart in the industry, and their commitment to innovation ensures that they remain at the forefront of technological advancements.In conclusion, the introduction of Custom Sapphire Dowel Pins by St.Cera Co., Ltd. represents a significant milestone for the company and further solidifies their position as a leading provider of high-quality precision ceramic parts. With their exceptional hardness, thermal and chemical resistance, and precision manufacturing process, these dowel pins are poised to make a lasting impact in a wide range of industries. St.Cera's continued commitment to excellence and innovation positions them as a trusted partner for businesses seeking reliable and high-performance precision ceramic parts.

High-Quality Si3n4 Ceramic Rods for Custom Applications

St.Cera Co., Ltd., a private high-tech enterprise specializing in precision ceramic manufacturing, has recently announced the launch of their latest product - Custom Si3n4 Ceramic Rods. These ceramic rods are designed to meet the growing demand for high-quality and durable materials in various industries.St.Cera Co., Ltd. has established a strong reputation in the precision ceramic manufacturing industry, with a dedicated team of top-ranking experts and engineers. The company's core competencies lie in research and development, manufacturing, and marketing of precision ceramic parts, and their latest product launch is a testament to their commitment to innovation and excellence.The Custom Si3n4 Ceramic Rods are made from a high-quality silicon nitride ceramic material, which offers exceptional mechanical and thermal properties. This makes them ideal for use in a wide range of applications, including but not limited to, aerospace, automotive, and medical industries. The superior performance of these ceramic rods makes them a preferred choice for companies looking for reliable and long-lasting materials.The use of silicon nitride ceramic also allows for enhanced resistance to wear, corrosion, and thermal shock, making the Custom Si3n4 Ceramic Rods a cost-effective and durable solution for various industrial applications. The exceptional strength and hardness of the material make it suitable for use in high-stress environments, where traditional metal components may not perform as effectively.St.Cera Co., Ltd.'s expertise in precision ceramic manufacturing ensures that the Custom Si3n4 Ceramic Rods are produced with utmost precision and consistency. The company's state-of-the-art manufacturing facilities and stringent quality control measures guarantee that each rod meets the highest standards of performance and reliability. Customers can be confident in the quality of the product and its suitability for their specific applications.In addition to the exceptional mechanical properties of the Custom Si3n4 Ceramic Rods, St.Cera Co., Ltd. also offers customization options to meet the unique requirements of their customers. This includes the ability to produce rods in various dimensions, shapes, and surface finishes, allowing for seamless integration into existing systems or applications. The company's dedication to meeting the specific needs of their clients sets them apart as a leader in the precision ceramic manufacturing industry.To support the launch of the Custom Si3n4 Ceramic Rods, St.Cera Co., Ltd. will be offering comprehensive technical support and customer service to ensure a smooth and successful integration of the product into customers' operations. The company's team of experts will be available to provide guidance and assistance throughout the process, from product selection to installation and ongoing maintenance.With the launch of the Custom Si3n4 Ceramic Rods, St.Cera Co., Ltd. continues to demonstrate their commitment to delivering innovative and high-quality solutions to their customers. The company's dedication to research and development, combined with their manufacturing expertise, positions them as a trusted partner for companies seeking reliable and durable precision ceramic parts.As industries continue to demand materials that offer superior performance and longevity, the Custom Si3n4 Ceramic Rods from St.Cera Co., Ltd. are poised to meet these needs effectively. With their exceptional mechanical properties, customization options, and comprehensive technical support, these ceramic rods are set to make a significant impact in a wide range of industrial applications.In conclusion, St.Cera Co., Ltd.'s launch of the Custom Si3n4 Ceramic Rods reaffirms their position as a leader in the precision ceramic manufacturing industry. The company's expertise, dedication to quality, and commitment to customer satisfaction make them a preferred partner for companies seeking high-performance ceramic solutions. As the demand for durable and reliable materials continues to grow, St.Cera Co., Ltd. is well-equipped to meet these needs with their latest product offering.

Alumina Wafer Arm: A Customized Solution for Enhanced Performance

Custom Alumina Wafer Arm Revolutionizes Precision Ceramic ManufacturingSt.Cera Co., Ltd. is making waves in the precision ceramic manufacturing industry with their latest innovation - the Custom Alumina Wafer Arm. This breakthrough product is set to revolutionize the way precision ceramic parts are manufactured, promising increased efficiency, precision, and performance.St.Cera Co., Ltd. is a private high-tech enterprise specializing in precision ceramic manufacturing. The company has a team of top-ranking experts and engineers in precision ceramic manufacturing. Their core competencies lie in research and development, manufacturing, and marketing of precision ceramic parts. With a proven track record of delivering high-quality products to their customers, St.Cera Co., Ltd. is at the forefront of innovation in the industry.The Custom Alumina Wafer Arm is the latest addition to St.Cera Co., Ltd.'s product line, and it is already creating a buzz among industry professionals. This innovative product is designed to meet the growing demand for high-performance and reliable precision ceramic parts in various industries, including semiconductor, aerospace, medical, and automotive.The key feature of the Custom Alumina Wafer Arm is its ability to provide unparalleled precision and consistency in manufacturing. The use of advanced materials and cutting-edge manufacturing techniques ensures that each wafer arm meets the highest standards of quality and performance. This level of precision is essential for industries that rely on precision ceramic parts to power their critical applications.The Custom Alumina Wafer Arm also offers improved durability and resistance to wear and tear, making it a cost-effective solution for businesses looking to streamline their manufacturing processes. Its unique design and properties make it suitable for a wide range of applications, from wafer handling in semiconductor manufacturing to precision positioning in medical equipment.In addition to its superior performance, the Custom Alumina Wafer Arm is customizable to meet the specific needs of individual customers. St.Cera Co., Ltd. works closely with their clients to understand their unique requirements and provides tailored solutions that align with their production goals. This level of customization sets the Custom Alumina Wafer Arm apart from other products on the market, making it an attractive option for businesses looking to enhance their manufacturing capabilities.With the introduction of the Custom Alumina Wafer Arm, St.Cera Co., Ltd. is poised to solidify its position as a leader in precision ceramic manufacturing. The company's commitment to innovation and excellence has driven the development of this groundbreaking product, and it is set to make a significant impact on the industry. By offering a solution that addresses the evolving needs of their customers, St.Cera Co., Ltd. is setting the standard for precision ceramic parts manufacturing.Industry professionals and businesses alike are eager to experience the benefits of the Custom Alumina Wafer Arm. Its potential to streamline manufacturing processes, improve product performance, and reduce operational costs has already captured the attention of key players in the industry. As the demand for precision ceramic parts continues to grow, the Custom Alumina Wafer Arm is positioned to be a game-changer for businesses looking to stay ahead of the curve.St.Cera Co., Ltd. is committed to delivering innovative solutions that drive progress in the precision ceramic manufacturing industry. The introduction of the Custom Alumina Wafer Arm is a testament to their dedication to pushing the boundaries of what is possible in precision ceramic manufacturing. As they continue to push the envelope with their cutting-edge products, St.Cera Co., Ltd. is poised to shape the future of the industry and set new standards for excellence.

Discover the Latest Innovations in Ceramic Tube Technology

Beijing, China - In a bid to revolutionize the ceramic tube industry, a leading company has recently introduced a groundbreaking product that is set to redefine the way we use and perceive ceramic tubes. The new product, Beo Ceramic Tube, promises to provide unparalleled performance and durability, making it a game-changer in various industrial applications.The Beo Ceramic Tube is the latest innovation from the renowned company, which has been at the forefront of producing high-quality ceramic products for over two decades. With a strong commitment to technological advancement and product development, the company has consistently pushed the boundaries of what is possible with ceramic materials. The introduction of the Beo Ceramic Tube is yet another testament to their dedication to innovation and excellence.One of the key features of the Beo Ceramic Tube is its exceptional strength and durability. Made from high-grade ceramic materials, the tube is capable of withstanding extreme temperatures and harsh operating conditions, making it ideal for a wide range of industrial applications. Whether it is used in the metallurgical industry, chemical plants, or power generation facilities, the Beo Ceramic Tube is designed to deliver superior performance and reliability.Furthermore, the Beo Ceramic Tube offers excellent thermal insulation properties, making it an ideal choice for applications that require high-temperature resistance. This not only enhances the efficiency of industrial processes but also helps in reducing energy consumption, making it an environmentally friendly option. Additionally, the tube's resistance to corrosion and chemical attacks further adds to its longevity, making it a cost-effective solution for various industrial needs.In addition to its exceptional physical properties, the Beo Ceramic Tube is also designed for ease of installation and maintenance. Its lightweight and easy-to-handle design make it convenient for technicians to work with, saving both time and effort during installation and replacement. This, coupled with its long service life, makes it a highly economical choice for industrial facilities looking to minimize downtime and maintenance costs.The company behind the Beo Ceramic Tube is committed to providing comprehensive support to its customers. With a team of experienced engineers and technical experts, they offer personalized consulting services to help customers select the right ceramic tube solutions for their specific needs. This customer-centric approach has earned them a reputation for being a trusted partner in the industry, and the introduction of the Beo Ceramic Tube is poised to further solidify their position as a leading provider of ceramic products.The Beo Ceramic Tube has already garnered attention and positive feedback from industry professionals who have had the opportunity to test its capabilities. Many have praised its exceptional performance and durability, noting that it has exceeded their expectations and outperformed other ceramic tube options currently available in the market.With the introduction of the Beo Ceramic Tube, the company aims to set a new standard for ceramic tube technology and provide industrial customers with a reliable and high-performance solution that meets the demands of modern industrial applications. As the industry continues to evolve, the company remains committed to pushing the boundaries of ceramic material technology and delivering innovative solutions that address the evolving needs of its customers.In conclusion, the Beo Ceramic Tube represents a significant advancement in ceramic tube technology and is set to make a lasting impact on various industrial sectors. With its exceptional strength, durability, and thermal insulation properties, it is poised to become the go-to choice for industrial applications that require high-performance ceramic tubes. As the company continues to drive innovation and excellence in the industry, the Beo Ceramic Tube stands as a testament to their commitment to pushing the boundaries of what is possible with ceramic materials.

New Breakthrough in Semiconductor Technology: Advances in Aln Wafer Arm Development

Aln Wafer Arm, a leading technology company in the semiconductor industry, has recently announced an exciting new development in the field of wafer technology. The company, known for its innovative approach to semiconductor manufacturing, has made a significant breakthrough with the launch of a new and advanced wafer technology that is set to revolutionize the industry.With a strong focus on research and development, Aln Wafer Arm has been able to develop a cutting-edge wafer technology that promises to deliver unprecedented performance and efficiency. The new wafer technology is designed to meet the growing demand for higher performing and more reliable semiconductor products in various applications such as automotive, telecommunications, and consumer electronics.The company's commitment to innovation and technology advancement has been a key driving force behind the development of this groundbreaking wafer technology. By leveraging its expertise in semiconductor manufacturing and materials science, Aln Wafer Arm has successfully engineered a wafer solution that offers superior performance and reliability, while also being cost-effective and scalable.In addition to its technological advancements, Aln Wafer Arm has also invested heavily in state-of-the-art manufacturing facilities and processes to ensure the highest quality and consistency in its products. The company's dedication to quality control and rigorous testing procedures has earned it a reputation for delivering top-notch semiconductor products that meet the stringent requirements of its customers.Furthermore, Aln Wafer Arm has built a strong track record of collaborating with leading industry partners and customers to co-develop and optimize its wafer technology for specific applications. This collaborative approach has allowed the company to gain valuable insights and feedback from the market, enabling it to continuously improve and refine its products to better address the evolving needs of the industry.The launch of this new wafer technology comes at a time when the semiconductor industry is experiencing rapid growth and innovation. As demand for high-performance semiconductor products continues to rise, Aln Wafer Arm is well-positioned to capitalize on this trend and establish itself as a key player in the market.With its advanced wafer technology and strong commitment to technological innovation, Aln Wafer Arm is poised to make a significant impact on the semiconductor industry. The company's cutting-edge products are set to drive the next wave of technological advancements in various industries, and its dedication to quality and customer satisfaction will undoubtedly set new standards for the industry.As Aln Wafer Arm continues to push the boundaries of wafer technology, it is clear that the company's innovative approach and relentless pursuit of excellence will pave the way for a new era of semiconductor manufacturing. With its unwavering commitment to innovation and quality, Aln Wafer Arm is set to revolutionize the semiconductor industry and set new benchmarks for performance and reliability in wafer technology.

High-Quality Sapphire Rod for Various Applications

Custom Sapphire Rod: The Next Level of Precision Ceramic ManufacturingAs technology continues to advance at an unprecedented rate, the demand for high-quality precision ceramic parts has never been greater. St.Cera Co., Ltd. has risen to the occasion, establishing itself as a leader in the field of precision ceramic manufacturing. With their recent introduction of the Custom Sapphire Rod, the company has once again proven their commitment to innovation and excellence.St.Cera Co., Ltd. is a private high-tech enterprise that has been at the forefront of precision ceramic manufacturing for many years. Their team of top-ranking experts and engineers is dedicated to pushing the boundaries of what is possible in this field. Their core competencies lie in research and development, manufacturing, and marketing of precision ceramic parts. With a focus on precision, quality, and reliability, St.Cera Co., Ltd. has established themselves as a trusted partner for companies in a wide range of industries.The Custom Sapphire Rod is the latest product to come out of St.Cera Co., Ltd.'s cutting-edge manufacturing facilities. Made from high-quality sapphire, a material known for its exceptional hardness and durability, the Custom Sapphire Rod is designed to meet the demanding needs of modern technology. Whether used in aerospace, medical devices, or high-end electronics, this product is poised to redefine what is possible in precision ceramic manufacturing.The Custom Sapphire Rod offers a number of key advantages over traditional ceramic parts. Firstly, sapphire is one of the hardest materials available, second only to diamond. This means that the Custom Sapphire Rod is able to withstand extremely high temperatures and pressures without compromising its structural integrity. As a result, it is an ideal choice for applications that require exceptional strength and durability.In addition to its strength, the Custom Sapphire Rod also offers superior optical properties. Sapphire is renowned for its transparency and clarity, making it an excellent choice for optical components such as lenses and prisms. This opens up a whole new world of possibilities for engineers and designers, allowing them to create products that were previously unattainable with traditional ceramic materials.Furthermore, the Custom Sapphire Rod is highly resistant to chemical corrosion, making it an excellent choice for applications where exposure to harsh chemicals is a concern. This, combined with its exceptional hardness, makes it a versatile and reliable option for a wide range of industries.St.Cera Co., Ltd. has invested heavily in state-of-the-art manufacturing equipment and processes to ensure that the Custom Sapphire Rod meets the highest standards of quality and precision. Every rod is meticulously crafted to exact specifications, ensuring uniformity and consistency across every unit. This dedication to quality has earned St.Cera Co., Ltd. a reputation for excellence in the precision ceramic manufacturing industry.The introduction of the Custom Sapphire Rod is a testament to St.Cera Co., Ltd.'s ongoing commitment to innovation and customer satisfaction. By pushing the boundaries of what is possible in precision ceramic manufacturing, they have once again demonstrated their leadership in the field. As technology continues to evolve, it is clear that St.Cera Co., Ltd. will remain at the forefront, providing the high-quality precision ceramic parts that the modern world demands.In conclusion, the Custom Sapphire Rod is a game-changer in the field of precision ceramic manufacturing. With its exceptional strength, optical properties, and chemical resistance, it is poised to revolutionize a wide range of industries. As St.Cera Co., Ltd. continues to lead the way in research and development, there is no doubt that the future of precision ceramic manufacturing is in good hands.

High-Quality Custom Si3n4 Ceramic Tube for Your Needs

St.Cera Co., Ltd., a private high-tech enterprise specializing in precision ceramic manufacturing, has recently announced the launch of a new custom Si3N4 ceramic tube. This new product is expected to meet the growing demand for high-quality precision ceramic parts in various industries.The Si3N4 ceramic tube is a key component in many industrial applications, including aerospace, semiconductor manufacturing, medical devices, and more. With its excellent thermal and mechanical properties, the Si3N4 ceramic tube is well-suited for use in high-temperature and corrosive environments. Its high strength, thermal shock resistance, and wear resistance make it an ideal choice for demanding applications.St.Cera Co., Ltd. has leveraged its team of top-ranking experts and engineers in precision ceramic manufacturing to develop the custom Si3N4 ceramic tube. The company's core competencies in research and development, manufacturing, and marketing of precision ceramic parts have enabled them to create a product that meets the stringent requirements of today's industries."We are excited to introduce our custom Si3N4 ceramic tube to the market," said a spokesperson for St.Cera Co., Ltd. "This product represents the latest in precision ceramic technology and embodies our commitment to delivering innovative solutions to our customers. We believe that the Si3N4 ceramic tube will offer unmatched performance and reliability in a wide range of applications."The launch of the custom Si3N4 ceramic tube comes at a time when the demand for high-quality precision ceramic parts is on the rise. Industries such as aerospace, automotive, electronics, and healthcare are increasingly turning to advanced ceramic materials for their unique combination of properties, which include high temperature resistance, electrical insulation, and chemical inertness.St.Cera Co., Ltd. is well-positioned to capitalize on this growing demand, thanks to its extensive expertise in precision ceramic manufacturing. The company's state-of-the-art production facilities and strict quality control processes ensure that the custom Si3N4 ceramic tube meets the highest standards of performance and reliability.In addition to the custom Si3N4 ceramic tube, St.Cera Co., Ltd. offers a comprehensive range of precision ceramic parts, including rods, plates, nozzles, and crucibles. Each of these products undergoes rigorous testing to ensure consistency and quality, making them ideal choices for critical applications where performance and reliability are paramount.As the market for precision ceramic parts continues to expand, St.Cera Co., Ltd. remains committed to pushing the boundaries of ceramic technology. The company's ongoing investment in research and development, coupled with its dedication to customer satisfaction, positions it as a leader in the field of precision ceramics."We are constantly exploring new materials and manufacturing techniques to improve our products and meet the evolving needs of our customers," said the spokesperson. "Our goal is to provide innovative solutions that deliver exceptional value and performance, and we believe that the custom Si3N4 ceramic tube is a testament to that commitment."The custom Si3N4 ceramic tube is now available for purchase, and interested customers are encouraged to contact St.Cera Co., Ltd. for more information. With its outstanding properties and the backing of a reputable and experienced manufacturer, the custom Si3N4 ceramic tube is expected to make a significant impact in the world of precision ceramic parts.

Ceramic Rod: A Custom Solution for Extended Durability and Precision

St. Cera Co., Ltd. Introduces Custom Beo Ceramic Rod for Precision ApplicationsSt. Cera Co., Ltd. is proud to announce the introduction of their new custom Beo ceramic rod, designed for precision applications in various industries. As a private high-tech enterprise specializing in precision ceramic manufacturing, St. Cera Co., Ltd. has a team of top-ranking experts and engineers who have developed this innovative product to meet the growing demand for high-performance ceramic components.The custom Beo ceramic rod is a result of the company's core competencies in research and development, manufacturing, and marketing of precision ceramic parts. This new product is a testament to St. Cera Co., Ltd.'s commitment to continuous improvement and innovation in the field of ceramic manufacturing.The custom Beo ceramic rod offers a range of benefits, making it an ideal choice for precision applications. One of the key features of the Beo ceramic rod is its exceptional hardness and wear resistance, making it suitable for use in high-stress environments where traditional materials may fail. The ceramic rod also offers excellent thermal stability, allowing it to maintain its properties in extreme temperature conditions.In addition to its physical properties, the custom Beo ceramic rod is also highly resistant to corrosion and chemical attack, making it suitable for use in harsh industrial environments. Its inherent electrical insulation properties make it an excellent choice for applications in the electronics and semiconductor industries.The custom Beo ceramic rod is available in a variety of sizes and configurations, allowing for flexibility in design and application. This versatility makes it an attractive choice for engineers and designers looking for a high-performance ceramic component to meet their specific requirements.St. Cera Co., Ltd. is confident that the custom Beo ceramic rod will set a new standard for precision ceramic components in the industry. With its exceptional properties and performance, this innovative product is expected to find widespread use in a variety of applications, ranging from aerospace and automotive to medical and semiconductor industries.The introduction of the custom Beo ceramic rod further strengthens St. Cera Co., Ltd.'s position as a leading provider of precision ceramic components. The company's dedication to research and development, coupled with its state-of-the-art manufacturing capabilities, has enabled them to bring this cutting-edge product to market.In conclusion, the custom Beo ceramic rod from St. Cera Co., Ltd. represents a significant advancement in the field of precision ceramic manufacturing. With its exceptional properties and performance, this innovative product is poised to make a lasting impact in various industries, offering engineers and designers a high-performance solution for their specific needs. St. Cera Co., Ltd. continues to demonstrate its commitment to excellence and innovation, solidifying its reputation as a premier provider of precision ceramic components.