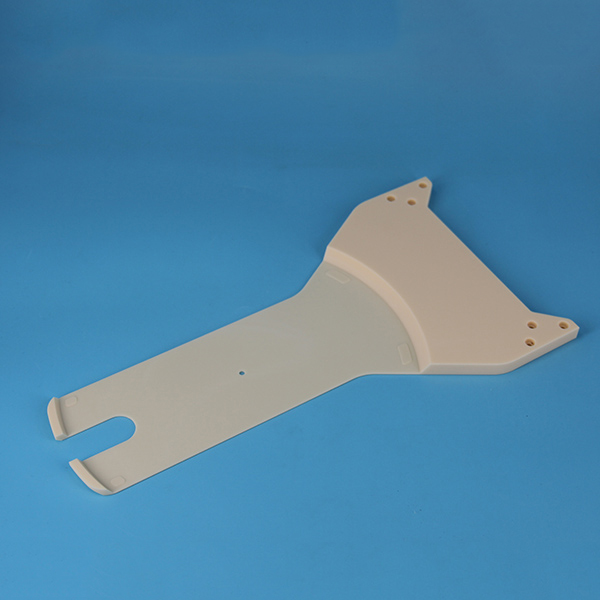

Durable Ceramic Laser Nozzle for Precision Cutting and Welding

By:Admin

The Ceramic Laser Nozzle, which is free of brand name for competitive reasons, is a cutting-edge product designed to improve the efficiency and precision of laser cutting and welding processes. Made from high-quality precision ceramics, the nozzle exhibits exceptional heat resistance and durability, making it an ideal choice for industrial applications.

The nozzle’s design and manufacturing process are a testament to St.Cera’s commitment to research and development in the precision ceramic industry. The company’s core competencies in precision ceramic manufacturing have been instrumental in the creation of this groundbreaking product. Through rigorous testing and refinement, St.Cera has successfully developed a nozzle that meets the stringent requirements of modern laser cutting and welding processes.

St.Cera Co., Ltd. is renowned for its dedication to producing high-quality precision ceramic components that cater to a wide range of industries. With a focus on research, development, manufacturing, and marketing of precision ceramic parts, the company has established itself as a reliable partner for businesses seeking innovative solutions for their manufacturing needs.

The Ceramic Laser Nozzle is a testament to St.Cera’s expertise and commitment to advancing the capabilities of precision ceramics in industrial applications. By leveraging the unique properties of ceramics, the company has been able to develop a product that offers superior performance and longevity compared to traditional metal nozzles.

In addition to its exceptional heat resistance, the Ceramic Laser Nozzle exhibits excellent wear resistance, ensuring consistent performance over extended periods of use. This characteristic is particularly valuable for businesses looking to minimize downtime and maintenance costs associated with laser cutting and welding equipment.

Moreover, the nozzle’s precision engineering ensures consistent and reliable operation, allowing businesses to achieve higher levels of accuracy and efficiency in their manufacturing processes. By reducing the need for frequent maintenance and replacement, the Ceramic Laser Nozzle offers a cost-effective solution for businesses seeking to optimize their operations.

With its innovative approach to precision ceramic manufacturing, St.Cera Co., Ltd. has positioned itself as a leading provider of advanced ceramic components for industrial applications. The company’s dedication to research and development has enabled it to push the boundaries of what is possible with ceramics, resulting in the creation of the Ceramic Laser Nozzle.

As businesses continue to seek ways to improve the efficiency and reliability of their manufacturing processes, the Ceramic Laser Nozzle represents a significant advancement in the field of precision ceramic components. With its unrivaled heat resistance, durability, and precision engineering, the nozzle is poised to become an essential tool for businesses operating in the laser cutting and welding industries.

St.Cera’s commitment to innovation and excellence has made it a trusted partner for businesses seeking high-quality precision ceramic components. The launch of the Ceramic Laser Nozzle further solidifies the company’s reputation as a leader in the industry and demonstrates its ongoing dedication to advancing the capabilities of precision ceramics in industrial settings.

Overall, the introduction of the Ceramic Laser Nozzle represents a significant milestone for St.Cera Co., Ltd. and a major advancement for the precision ceramic manufacturing industry as a whole. With its superior performance and reliability, the nozzle is set to revolutionize the way businesses approach laser cutting and welding processes, offering a compelling alternative to traditional metal components.

As St.Cera continues to push the boundaries of what is possible with precision ceramics, businesses can expect to benefit from a new generation of innovative and high-performance products that will help them achieve greater efficiency and reliability in their manufacturing operations. The Ceramic Laser Nozzle is just the beginning of what promises to be an exciting journey for St.Cera and the future of precision ceramic components.

Company News & Blog

High-Quality Alumina Ceramic Tubes: A Comprehensive Overview

St.Cera Co., Ltd. is making headlines with its high-quality alumina ceramic tubes, which have been gaining recognition for their exceptional performance and durability. The company is a private high-tech enterprise specializing in precision ceramic manufacturing and prides itself on its team of top-ranking experts and engineers in this field.Alumina ceramic tubes are widely used in various industries, such as electronics, automotive, and medical, due to their excellent thermal conductivity, high strength, and resistance to corrosion. St.Cera's alumina ceramic tubes are known for their exceptional quality and are a result of extensive research and development, manufacturing, and marketing efforts.The company's commitment to quality is evident in its rigorous production processes and strict quality control measures. St.Cera ensures that each alumina ceramic tube meets the highest standards and conforms to all industry certifications.St.Cera's alumina ceramic tubes are designed to withstand extreme temperatures, making them ideal for applications in high-temperature environments. They are also valued for their superior electrical insulation properties, making them essential components in electronics and semiconductor manufacturing.Another key feature of St.Cera's alumina ceramic tubes is their exceptional mechanical strength, which allows them to endure harsh operating conditions without compromising their performance. This makes them the preferred choice for applications requiring reliability and longevity.In addition to their physical properties, St.Cera's alumina ceramic tubes are also highly resistant to chemical corrosion, making them suitable for use in harsh chemical environments. This versatility has made them a popular choice across a wide range of industries.The company's commitment to innovation and continuous improvement has led to the development of alumina ceramic tubes that offer superior performance and reliability. St.Cera's dedication to research and development has enabled them to stay at the forefront of precision ceramic manufacturing, ensuring that their products consistently meet and exceed industry standards.St.Cera's alumina ceramic tubes have already garnered positive feedback from customers and industry experts alike. Their reputation for quality and performance has positioned them as a preferred supplier in the precision ceramic market.The company's extensive experience in precision ceramic manufacturing, coupled with its state-of-the-art facilities and cutting-edge technology, allows them to deliver high-quality alumina ceramic tubes that meet the diverse needs of their customers. Their proficiency in customizing solutions further enhances their ability to cater to specific requirements and ensure customer satisfaction.St.Cera's dedication to customer satisfaction extends beyond the quality of their products. The company prides itself on its responsive and professional customer service, ensuring that clients receive the support and assistance they need throughout the entire process, from inquiry to delivery.As St.Cera continues to make strides in the precision ceramic industry, their alumina ceramic tubes stand out as a testament to their expertise and dedication to excellence. The company's focus on quality, innovation, and customer satisfaction has positioned them as a leader in the market, and their high-quality alumina ceramic tubes are a reflection of their ongoing commitment to surpassing expectations.In conclusion, St.Cera Co., Ltd.'s high-quality alumina ceramic tubes have solidified the company's position as a leading supplier in the precision ceramic manufacturing industry. With their dedication to research, development, and customer satisfaction, St.Cera continues to set the standard for excellence in the production of alumina ceramic tubes.

Top-Quality Boron Nitride Ceramic Dowel Pins for Sale - Shop Now

St.Cera Co., Ltd., a private high-tech enterprise specializing in precision ceramic manufacturing, has recently introduced their latest product, high-quality Boron Nitride Ceramic Dowel Pins. With a team of top-ranking experts and engineers in precision ceramic manufacturing, the company has focused on research and development, manufacturing, and marketing of precision ceramic parts.Boron Nitride Ceramic Dowel Pins are a critical component in many high-precision applications and industries, including aerospace, automotive, defense, and semiconductor manufacturing. These advanced ceramic dowel pins offer exceptional thermal conductivity, high electrical insulation, and excellent mechanical strength, making them an ideal choice for demanding environments.St.Cera Co., Ltd. prides itself on producing superior quality ceramic products, and the introduction of Boron Nitride Ceramic Dowel Pins is a testament to their commitment to innovation and excellence. These ceramic dowel pins are manufactured using advanced techniques and high-quality materials, ensuring consistent performance and reliability in the most challenging conditions."The demand for high-quality ceramic dowel pins has been increasing across various industries, and we are pleased to offer our customers a superior solution with our Boron Nitride Ceramic Dowel Pins," said a spokesperson for St.Cera Co., Ltd. "Our expertise in precision ceramic manufacturing allows us to meet the exacting requirements of our customers, and we are confident that our new product will exceed their expectations."In addition to their exceptional physical properties, Boron Nitride Ceramic Dowel Pins also offer excellent chemical resistance and stability at high temperatures, making them suitable for use in harsh and corrosive environments. These attributes make them an ideal choice for applications where traditional metal dowel pins may not be suitable.The introduction of high-quality Boron Nitride Ceramic Dowel Pins further solidifies St.Cera Co., Ltd.'s position as a leading provider of precision ceramic components. With a focus on continuous improvement and investment in cutting-edge technology, the company is well-positioned to meet the evolving needs of their customers and the market.St.Cera Co., Ltd. has a strong commitment to quality, and their rigorous quality control processes ensure that every Boron Nitride Ceramic Dowel Pin meets the highest standards. By maintaining strict adherence to industry regulations and standards, the company ensures that its products consistently deliver outstanding performance and reliability.The company's dedication to precision ceramic manufacturing has earned them a reputation for excellence in the industry. Their ability to tailor solutions to meet specific customer requirements is a testament to their technical expertise and commitment to customer satisfaction.As the demand for high-performance ceramic components continues to grow, St.Cera Co., Ltd. remains at the forefront of the industry. With a focus on innovation and a dedication to delivering exceptional products, the company is well-equipped to support the evolving needs of their customers across various sectors.The introduction of high-quality Boron Nitride Ceramic Dowel Pins is a significant milestone for St.Cera Co., Ltd., and further demonstrates their leadership in precision ceramic manufacturing. With a strong emphasis on research and development, the company is well-positioned to continue driving innovation and delivering advanced ceramic solutions to meet the demands of today's highly specialized industries.In conclusion, St.Cera Co., Ltd.'s introduction of high-quality Boron Nitride Ceramic Dowel Pins reaffirms their commitment to delivering superior precision ceramic solutions. With a track record of excellence and a dedication to meeting the evolving needs of their customers, the company is well-positioned to continue leading the way in the precision ceramic manufacturing industry.

Top-Quality Ceramic Finger Manufacturers: Find the Best Options Here

St.Cera Co., Ltd. is a private high-tech enterprise specializing in precision ceramic manufacturing. The company has a team of top-ranking experts and engineers in precision ceramic manufacturing. Our core competencies lie in research and development, manufacturing, and marketing of precision ceramic parts. We are proud to announce that we have recently expanded our product line to include high-quality Bernoulli ceramic fingers.Bernoulli ceramic fingers are an essential component in many industries, including semiconductor manufacturing, robotics, and medical devices. They are designed to provide precise and reliable gripping and handling of delicate and sensitive materials. The unique properties of ceramic, such as its high hardness, wear resistance, and thermal stability, make it an ideal material for manufacturing Bernoulli fingers.At St.Cera Co., Ltd., we have leveraged our expertise in precision ceramic manufacturing to develop high-quality Bernoulli ceramic fingers that meet the demanding requirements of modern industries. Our Bernoulli fingers are manufactured using advanced ceramic materials and state-of-the-art manufacturing processes to ensure exceptional performance and durability.We understand the critical role that Bernoulli fingers play in ensuring the smooth operation of automated systems, which is why we have focused on delivering products of the highest quality. Our Bernoulli fingers are meticulously crafted to provide precise and consistent gripping force, which is essential for the safe and reliable handling of delicate materials.In addition to their exceptional performance, our Bernoulli ceramic fingers are also designed for easy integration into existing systems. We offer a range of standard sizes and configurations to accommodate a variety of gripping needs. Furthermore, we also provide custom design and manufacturing services to meet the specific requirements of our customers.With our dedication to quality and innovation, St.Cera Co., Ltd. has quickly become a leading manufacturer of high-quality Bernoulli ceramic fingers. Our products have been widely adopted by major companies in the semiconductor, robotics, and medical device industries, where precision and reliability are of the utmost importance.In addition to our Bernoulli fingers, we also offer a comprehensive range of precision ceramic parts and components to support the diverse needs of our customers. Whether it's for wear-resistant bearings, cutting tools, or insulating components, our precision ceramic products are trusted for their exceptional performance and quality.As a company committed to excellence, St.Cera Co., Ltd. continues to invest in research and development to push the boundaries of ceramic technology. We are constantly exploring new materials, processes, and design concepts to further improve the performance and capabilities of our products.In conclusion, our high-quality Bernoulli ceramic fingers are the result of our unwavering commitment to excellence and innovation. With their exceptional performance, reliability, and ease of integration, they have become the preferred choice for industries that demand the best. St.Cera Co., Ltd. looks forward to continuing to serve the needs of our customers with cutting-edge ceramic solutions and exceptional service.

Unique Ceramic Fork for Customization and Personalization

St.Cera Co., Ltd. unveils Custom Bernoulli Ceramic ForkSt.Cera Co., Ltd., a leading private high-tech enterprise specializing in precision ceramic manufacturing, has recently announced the launch of its latest innovation, the Custom Bernoulli Ceramic Fork. The company, which is renowned for its expertise in research and development, manufacturing, and marketing of precision ceramic parts, has once again demonstrated its commitment to pushing the boundaries of ceramic technology with this new product.The Custom Bernoulli Ceramic Fork is a testament to St.Cera's dedication to excellence and innovation in the field of precision ceramic manufacturing. With a team of top-ranking experts and engineers, the company has been at the forefront of developing cutting-edge ceramic products that offer superior performance, durability, and quality.The Bernoulli Ceramic Fork is named after the Swiss mathematician and physicist, Daniel Bernoulli, whose principle of fluid dynamics is the inspiration behind the design of this innovative product. The fork is crafted using the highest quality ceramic materials, ensuring exceptional strength, hardness, and resistance to wear and corrosion.One of the key features of the Custom Bernoulli Ceramic Fork is its unique design, which is optimized for precision and efficiency. The fork's ceramic construction allows for smooth and precise handling, making it ideal for use in a wide range of applications, including aerospace, medical devices, automotive engineering, and more.In addition to its exceptional performance, the Custom Bernoulli Ceramic Fork also offers significant advantages in terms of hygiene and safety. Ceramic materials are non-porous and resistant to bacteria, making them an ideal choice for applications where cleanliness and sterility are crucial. Furthermore, the fork's corrosion-resistant properties ensure that it remains in pristine condition even after prolonged use.The launch of the Custom Bernoulli Ceramic Fork underscores St.Cera's ongoing commitment to setting new standards in the precision ceramic manufacturing industry. By leveraging its expertise in materials science, engineering, and manufacturing, the company continues to develop innovative solutions that address the evolving needs of its customers in various sectors.Commenting on the launch of the Custom Bernoulli Ceramic Fork, a spokesperson for St.Cera Co., Ltd. said, "We are thrilled to introduce this groundbreaking product to the market. The Custom Bernoulli Ceramic Fork exemplifies our dedication to advancing ceramic technology and delivering exceptional quality to our customers. We believe that this product will set a new benchmark for precision and reliability in the industry."The announcement of the Custom Bernoulli Ceramic Fork has garnered significant attention from industry professionals, engineers, and researchers who recognize the potential of this innovative product to redefine standards in precision ceramic manufacturing. With its advanced design, superior performance, and robust construction, the Bernoulli Ceramic Fork is poised to make a significant impact in various sectors where precision and durability are paramount.As St.Cera Co., Ltd. continues to expand its presence in the global market, the launch of the Custom Bernoulli Ceramic Fork reaffirms the company's position as a leader in precision ceramic manufacturing. With its relentless focus on innovation, quality, and excellence, St.Cera is poised to shape the future of ceramic technology and set new benchmarks for performance and reliability in the industry.In conclusion, the introduction of the Custom Bernoulli Ceramic Fork is a testament to St.Cera's commitment to pushing the boundaries of ceramic technology and delivering exceptional quality to its customers. With its advanced design, superior performance, and robust construction, the Bernoulli Ceramic Fork is set to redefine standards in precision ceramic manufacturing and make a lasting impact in various industries. St.Cera Co., Ltd. continues to lead the way in advancing ceramic technology, and the launch of this innovative product reaffirms the company's position as a top-ranking expert in the field.

High-Quality Custom Zirconia Ceramic Roller: A Durable Solution for Various Applications

St.Cera Co., Ltd., a private high-tech enterprise specializing in precision ceramic manufacturing, has announced the launch of their new custom zirconia ceramic roller. This innovative product is set to revolutionize the industrial manufacturing sector with its advanced features and superior quality. The company, known for its expertise in research and development, manufacturing, and marketing of precision ceramic parts, is poised to make a significant impact with this latest addition to their product line.Zirconia ceramic is a highly durable and versatile material that is widely used in various industries for its exceptional properties. It is known for its high mechanical strength, wear and corrosion resistance, and low friction coefficient, making it an ideal choice for demanding applications. The custom zirconia ceramic roller, developed by St.Cera, is designed to offer maximum performance and reliability in industrial applications, where precision and durability are essential.The team of top-ranking experts and engineers at St.Cera has leveraged their extensive knowledge and experience in precision ceramic manufacturing to develop a custom zirconia ceramic roller that meets the highest standards of quality and performance. The roller is meticulously engineered to ensure smooth and precise operation, even in the most challenging environments. Its exceptional wear resistance and long service life make it a cost-effective solution for industries seeking to improve their production processes.In addition to its impressive mechanical properties, the custom zirconia ceramic roller offers excellent thermal stability, making it suitable for use in high-temperature applications. This feature makes it an ideal choice for industries such as steel manufacturing, glass production, and heat treatment processes, where consistent performance under extreme heat conditions is crucial.The launch of the custom zirconia ceramic roller reaffirms St.Cera's commitment to innovation and excellence in precision ceramic manufacturing. The company has been at the forefront of developing advanced ceramic solutions for a wide range of industrial applications, and the new roller is a testament to their dedication to meeting the evolving needs of their customers.St.Cera's extensive experience in the field of precision ceramic manufacturing sets them apart as a leading supplier of high-quality ceramic products. Their state-of-the-art manufacturing facilities and strict quality control processes ensure that every custom zirconia ceramic roller is produced to the highest standards, meeting the rigorous requirements of modern industrial applications."Our custom zirconia ceramic roller is the result of our relentless pursuit of excellence in ceramic engineering," said a spokesperson for St.Cera. "We are confident that this new product will empower our customers to enhance their manufacturing processes and achieve new levels of efficiency and reliability. It is a testament to our unwavering commitment to providing innovative solutions that address the complex challenges faced by industries today."The launch of the custom zirconia ceramic roller comes at a time when industries are increasingly turning to advanced materials to improve the performance and reliability of their production processes. As the demand for high-quality ceramic products continues to grow, St.Cera is well-positioned to meet the needs of customers looking for innovative solutions that offer unmatched performance and durability.With their new custom zirconia ceramic roller, St.Cera is set to make a significant impact in the industrial manufacturing sector, offering a product that combines cutting-edge technology with the superior quality that has become synonymous with the company. As industries continue to evolve and demand more advanced solutions, St.Cera remains committed to pushing the boundaries of ceramic engineering and delivering products that set new standards for performance and reliability.As the global economy continues to expand, the demand for high-quality precision ceramic products is expected to grow. With their extensive expertise and commitment to innovation, St.Cera is poised to play a key role in shaping the future of ceramic manufacturing, driving advancements in technology and meeting the evolving needs of industries around the world. The launch of their custom zirconia ceramic roller further solidifies their position as a leader in precision ceramic manufacturing and highlights their ongoing dedication to providing cutting-edge solutions to meet the challenges of today's industrial landscape.

High performance boron nitride ceramic rod for various industrial applications

Boron Nitride Ceramic Rod, a Breakthrough in Advanced Engineering The field of advanced engineering and materials science has taken a great leap forward with the introduction of Boron Nitride Ceramic Rod, a revolutionary new product that promises to revolutionize a wide range of industries. Created by a team of expert researchers and engineers at {}, this groundbreaking material offers exceptional thermal conductivity, high temperature and chemical resistance, and outstanding mechanical strength. The innovative properties of Boron Nitride Ceramic Rod make it an ideal choice for applications in aerospace, automotive, electronics, and many other fields.Boron Nitride Ceramic Rod is a high-performance material that is designed to exceed the limitations of traditional materials such as metal, plastic, and other ceramics. It is composed of a unique combination of boron and nitrogen atoms, arranged in a hexagonal lattice structure, which gives the material its exceptional properties. This structure allows Boron Nitride Ceramic Rod to exhibit high thermal conductivity, even at extremely high temperatures, making it an excellent choice for applications in the aerospace and automotive industries. Additionally, the material's resistance to chemicals and corrosion makes it a viable option for use in aggressive environments, and its exceptional mechanical strength allows for a wide range of engineering applications.The properties of Boron Nitride Ceramic Rod are unmatched by any other material currently available on the market, making it an attractive choice for a wide range of industries. With its high thermal conductivity, the material allows for efficient heat transfer, reducing the risk of overheating in electronic devices, automotive engines, and aerospace components. The material's exceptional resistance to chemicals and corrosion makes it an ideal choice for use in aggressive environments, including chemical processing plants and offshore platforms. Additionally, the high mechanical strength of Boron Nitride Ceramic Rod allows for its use in a wide range of engineering applications, including cutting tools, bearings, and high-performance components.Boron Nitride Ceramic Rod is set to revolutionize the way engineers and researchers approach advanced materials and engineering solutions. Its unique combination of properties makes it an attractive choice for a wide range of industries, where traditional materials may fall short. The material's high thermal conductivity, resistance to chemicals and corrosion, and outstanding mechanical strength make it a valuable asset for applications in aerospace, automotive, electronics, and many other fields. With its introduction, engineers and researchers will have a new tool at their disposal to push the boundaries of what is possible in advanced engineering and materials science.The development of Boron Nitride Ceramic Rod is a testament to the dedication and expertise of the team at {}. With years of experience in materials science and engineering, the company has been at the forefront of innovation in advanced materials. Their commitment to pushing the boundaries of what is possible has led to the creation of Boron Nitride Ceramic Rod, a breakthrough material that promises to revolutionize a wide range of industries. The company's dedication to excellence and innovation has positioned them as a leader in the field of advanced engineering and materials science, and with the introduction of Boron Nitride Ceramic Rod, they continue to set the standard for cutting-edge materials and engineering solutions.In conclusion, Boron Nitride Ceramic Rod is an exceptional material that promises to revolutionize a wide range of industries with its unique combination of properties. Its high thermal conductivity, resistance to chemicals and corrosion, and outstanding mechanical strength make it an ideal choice for applications in aerospace, automotive, electronics, and many other fields. With its introduction, engineers and researchers now have a valuable new tool at their disposal to push the boundaries of what is possible in advanced engineering and materials science. The development of Boron Nitride Ceramic Rod is a testament to the dedication and expertise of the team at {}, who continue to set the standard for cutting-edge materials and engineering solutions.

Beryllium Ceramics Sleeve: A Durable and Reliable Option for Industrial Applications

St.Cera Co., Ltd. Introduces Breakthrough Beryllium Ceramics SleeveSt.Cera Co., Ltd. is proud to announce the development of a breakthrough product in the field of precision ceramic manufacturing - the Beryllium Ceramics Sleeve. This innovative new product promises to revolutionize a wide range of industries, from electronics and aerospace to medical and automotive.St.Cera Co., Ltd. is a private high-tech enterprise specializing in precision ceramic manufacturing. The company has a team of top-ranking experts and engineers in precision ceramic manufacturing. Our core competencies lie in research and development, manufacturing, and marketing of precision ceramic parts.Beryllium ceramics are a class of materials that exhibit exceptional properties, including high heat and electrical conductivity, as well as excellent mechanical strength and corrosion resistance. These characteristics make them highly sought after in industries where high performance and reliability are paramount.The Beryllium Ceramics Sleeve is a testament to St.Cera's commitment to pushing the boundaries of ceramic engineering. Designed to meet the stringent demands of modern technology, this innovative product offers unparalleled performance and durability in a compact form factor.One of the key advantages of the Beryllium Ceramics Sleeve is its high thermal conductivity. This property allows for efficient heat dissipation, making it an ideal choice for applications where temperature management is critical. Whether it's in high-power electronics or aerospace components, the Beryllium Ceramics Sleeve ensures that heat is effectively managed, leading to improved performance and reliability.In addition to its thermal properties, the Beryllium Ceramics Sleeve also boasts excellent electrical conductivity. This makes it an ideal choice for applications where electrical insulation and high-speed signal transmission are required. From advanced medical devices to high-frequency communication systems, the Beryllium Ceramics Sleeve delivers exceptional electrical performance, ensuring reliable operation in even the most demanding environments.Furthermore, the mechanical strength of the Beryllium Ceramics Sleeve sets it apart from traditional ceramic materials. Its exceptional toughness and resistance to wear and tear make it an ideal choice for applications where reliability is paramount. Whether it's in automotive components or industrial machinery, the Beryllium Ceramics Sleeve excels in the most challenging operating conditions, ensuring long-term performance and durability.St.Cera Co., Ltd. has leveraged its expertise in precision ceramic manufacturing to develop the Beryllium Ceramics Sleeve using advanced production techniques and quality control processes. This ensures that each sleeve meets the highest standards of performance and reliability, making it the ideal choice for mission-critical applications.The Beryllium Ceramics Sleeve is just one example of St.Cera's ongoing commitment to innovation and excellence in the field of precision ceramics. With a focus on research and development, the company continues to push the boundaries of what is possible with ceramic materials, paving the way for new opportunities and advancements in a wide range of industries.St.Cera Co., Ltd. is dedicated to working closely with its customers to understand their unique needs and challenges, and to provide tailored solutions that deliver tangible benefits. Whether it's in the form of custom-designed components or advanced materials, the company is committed to supporting its customers in achieving their goals and driving innovation in their respective fields.In conclusion, the introduction of the Beryllium Ceramics Sleeve represents a significant milestone for St.Cera Co., Ltd. and the field of precision ceramic manufacturing. With its exceptional thermal and electrical properties, combined with outstanding mechanical strength, this innovative product offers a compelling solution for a wide range of applications. As the company continues to pursue excellence in innovation and quality, the Beryllium Ceramics Sleeve stands as a testament to St.Cera's commitment to delivering exceptional performance and reliability in precision ceramic products.

High-Quality Zirconia Cylinder for Custom Applications

St.Cera Co., Ltd., a private high-tech enterprise specializing in precision ceramic manufacturing, has recently launched a new product - the custom zirconia cylinder. This new product is expected to have a significant impact on the precision ceramic manufacturing industry due to its advanced technology and exceptional quality. The custom zirconia cylinder is the result of extensive research and development efforts by St.Cera Co., Ltd. The company boasts a team of top-ranking experts and engineers in precision ceramic manufacturing, who have dedicated their expertise to creating innovative products that meet the highest standards of quality and performance. Zirconia is known for its exceptional durability and resistance to wear, making it an ideal material for precision ceramic components. The custom zirconia cylinder is designed to meet the demanding requirements of various industries, including medical, aerospace, and automotive. Its superior strength and reliability make it an excellent choice for applications where precision and longevity are essential. In addition to its superior performance, the custom zirconia cylinder is also highly customizable, allowing customers to tailor it to their specific needs. This level of flexibility sets St.Cera Co., Ltd. apart from its competitors, as it demonstrates the company's commitment to meeting the unique needs of its clients. The launch of the custom zirconia cylinder is a significant milestone for St.Cera Co., Ltd. and reaffirms the company's position as a leader in precision ceramic manufacturing. With its advanced technology and exceptional quality, the custom zirconia cylinder is expected to set a new standard for precision ceramic components and solidify St.Cera Co., Ltd.'s reputation as an industry pioneer. In order to meet the growing demand for the custom zirconia cylinder, St.Cera Co., Ltd. has expanded its manufacturing capabilities and invested in state-of-the-art equipment. This strategic investment demonstrates the company's commitment to providing its customers with the highest quality products and ensuring that it can meet the increased production requirements. The launch of the custom zirconia cylinder represents a significant opportunity for St.Cera Co., Ltd. to expand its presence in the precision ceramic manufacturing industry. By offering a product that excels in both performance and flexibility, the company is well-positioned to attract new customers and strengthen its relationships with existing clients. St.Cera Co., Ltd. is confident that the custom zirconia cylinder will be well-received by the market, and the company is committed to providing exceptional customer service and technical support to ensure the success of this new product. Overall, the launch of the custom zirconia cylinder represents a major advancement in the precision ceramic manufacturing industry, and St.Cera Co., Ltd. is poised to capitalize on this opportunity. With its dedication to innovation and excellence, the company is well-positioned to shape the future of precision ceramic components and solidify its position as a leader in the industry.

Ceramic Finger Factory Offers Custom Bernoulli Products

Custom Ceramic Finger Factory Sets New Standards in Finger ProductionIn the ever-evolving world of industrial ceramics, Custom Ceramic Finger Factory has carved out a niche for themselves as a leader in the production of high-quality ceramic fingers for a variety of industrial applications. The company, based in [location], has recently set new standards with their innovative use of Bernoulli's principle in the production of ceramic fingers.The Bernoulli principle, named after the Swiss mathematician Daniel Bernoulli, states that as the speed of a fluid increases, its pressure decreases. This principle has long been applied in various fields, including aviation, fluid dynamics, and even medical devices. Custom Ceramic Finger Factory has taken this principle and adapted it to their production process, resulting in a significant improvement in the quality and performance of their ceramic fingers.The company's production process begins with the careful selection of high-quality ceramic materials, which are then shaped and molded into the desired finger designs. The use of Bernoulli's principle comes into play during the firing and cooling stages of the production process. By carefully controlling the speed and direction of the airflow during these stages, Custom Ceramic Finger Factory is able to achieve a more consistent and uniform distribution of the ceramic material, resulting in fingers that are stronger, more durable, and better suited for a wider range of industrial applications.The application of the Bernoulli principle has allowed Custom Ceramic Finger Factory to push the boundaries of what is possible in terms of ceramic finger production. The company's fingers are now able to withstand higher levels of wear and tear, making them ideal for use in demanding industrial environments. Additionally, the improved uniformity and consistency of the fingers have resulted in better performance and reliability for the end users.In a statement, the company's CEO expressed their excitement about the new developments in their production process, stating, "We are thrilled to be at the forefront of ceramic finger production. By leveraging the principles of fluid dynamics, we have been able to create a product that sets new standards for quality and performance. We are confident that our customers will be delighted with the improvements that this new process brings."Custom Ceramic Finger Factory has a long history of innovation and excellence in the field of industrial ceramics. The company has built a reputation for delivering high-quality products that meet and exceed the needs of their customers. With the introduction of their new and improved ceramic fingers, the company is poised to further solidify its position as a leader in the industry.Looking ahead, Custom Ceramic Finger Factory is committed to continuing their investment in research and development, with the goal of further refining their production processes and expanding their range of ceramic finger products. The company is also exploring opportunities for collaboration with other industry leaders to explore new applications for their innovative ceramic fingers.In conclusion, Custom Ceramic Finger Factory has raised the bar for ceramic finger production with their innovative use of Bernoulli's principle. The company's commitment to excellence and their willingness to embrace new technologies and methods have resulted in a product that is truly best-in-class. As industrial applications continue to evolve and demand for high-quality ceramic fingers grows, Custom Ceramic Finger Factory is well-positioned to meet and exceed the needs of their customers.

High-Quality Custom Sapphire Tube for Various Applications

Custom Sapphire Tube, the leading manufacturer and supplier of high-quality sapphire tubes, has announced the launch of its newest product line. This new line of sapphire tubes is designed to meet the increasing demand for advanced materials in various industries such as aerospace, defense, and medical technology.Sapphire is a versatile material known for its exceptional hardness, high transparency, and resistance to harsh chemicals and extreme temperatures. These properties make sapphire tubes ideal for a wide range of applications, including optical and electronic components, chemical processing, and high-pressure systems.Custom Sapphire Tube has been at the forefront of sapphire technology for over two decades, providing innovative solutions to meet the unique needs of its customers. The company's state-of-the-art manufacturing facilities and cutting-edge production techniques enable it to produce sapphire tubes with precise dimensions, exceptional surface finish, and superior optical clarity.The new product line from Custom Sapphire Tube includes sapphire tubes in various sizes, from small diameters suitable for microfluidic applications to large diameters for high-pressure and high-temperature environments. Customers can also choose from a range of thickness options to meet their specific requirements.In addition to standard sapphire tubes, Custom Sapphire Tube also offers custom fabrication services, allowing customers to order sapphire tubes with unique configurations, such as flanges, threads, and tapered ends. The company's team of experienced engineers and technicians work closely with customers to develop tailored solutions that meet their exact specifications and performance criteria."We are excited to introduce our new line of sapphire tubes, which represents the latest advancements in sapphire material technology," said the spokesperson for Custom Sapphire Tube. "Our commitment to quality and innovation has allowed us to develop sapphire tubes that offer unparalleled performance and reliability in the most demanding applications."The new product line from Custom Sapphire Tube is expected to address the growing demand for high-performance sapphire tubes in industries such as aerospace, defense, and medical technology. The exceptional properties of sapphire, including its high thermal conductivity, chemical inertness, and optical transparency, make it an ideal material for critical components in these industries.Sapphire tubes are used in a wide range of applications, including laser systems, sensors, and high-pressure vessels, where their durability and performance characteristics are essential. Custom Sapphire Tube's sapphire tubes are designed to withstand extreme conditions and provide long-term reliability, making them a preferred choice for mission-critical applications.With its new product line, Custom Sapphire Tube aims to further solidify its position as a leading supplier of sapphire tubes for demanding industrial and scientific applications. The company's commitment to quality, innovation, and customer satisfaction ensures that its sapphire tubes meet the highest standards and exceed customer expectations.To learn more about Custom Sapphire Tube and its new product line of sapphire tubes, visit their website or contact their customer support team for further information and inquiries.