New Ceramic Pin Unveiled as Latest Innovation

By:Admin

St.Cera Co., Ltd. is making waves in the precision ceramic manufacturing industry with its latest innovation, the Beo Ceramic Pin. The Beo Ceramic Pin is a game-changer in the field of precision ceramic parts, offering unparalleled performance and durability.

St.Cera Co., Ltd. is a private high-tech enterprise specializing in precision ceramic manufacturing. The company has a team of top-ranking experts and engineers in precision ceramic manufacturing. Their core competencies lie in research and development, manufacturing, and marketing of precision ceramic parts. Their dedication to innovation and quality has positioned them as a leader in the industry.

The Beo Ceramic Pin is the latest testament to the company's commitment to excellence. It is designed to meet the evolving needs of industries that rely on precision ceramic parts for their operations. The pin is manufactured using the latest technologies and cutting-edge materials, ensuring superior performance and longevity.

One of the key features of the Beo Ceramic Pin is its exceptional durability. Unlike traditional metal pins, the Beo Ceramic Pin is highly resistant to wear and corrosion, making it ideal for use in demanding industrial applications. Its superior thermal and electrical insulation properties further enhance its suitability for a wide range of uses.

In addition to its durability, the Beo Ceramic Pin also offers unmatched precision. Its advanced manufacturing process ensures tight tolerances and consistent quality, making it the top choice for industries that require precise and reliable components. The pin's excellent dimensional stability and resistance to deformation further underscore its superiority.

The Beo Ceramic Pin has already garnered attention from various industries, including electronics, aerospace, automotive, and medical. Its versatility and high performance make it a valuable asset for manufacturers looking to improve the quality and reliability of their products. Furthermore, its ability to withstand extreme conditions and harsh environments opens up new possibilities for applications in challenging settings.

St.Cera Co., Ltd. is proud to introduce the Beo Ceramic Pin as part of its ongoing commitment to innovation and customer satisfaction. The company's dedication to research and development has enabled them to push the boundaries of precision ceramic manufacturing, setting new standards for quality and performance.

The Beo Ceramic Pin is just one example of St.Cera Co., Ltd.'s ability to deliver groundbreaking solutions to the market. With a strong focus on technology and expertise, the company continues to lead the way in the development of advanced ceramic components that address the evolving needs of modern industries.

The introduction of the Beo Ceramic Pin is a significant milestone for St.Cera Co., Ltd., and it reflects their relentless pursuit of excellence. The company's unwavering dedication to quality and innovation has solidified its reputation as a trusted partner for businesses seeking high-quality precision ceramic parts.

Moving forward, St.Cera Co., Ltd. is poised to further expand its product portfolio and capabilities, ensuring that it remains at the forefront of the precision ceramic manufacturing industry. With a steadfast commitment to excellence, the company is well-positioned to continue driving progress and shaping the future of precision ceramic components.

Company News & Blog

Durable Alumina Ceramic Pin for Industrial Use

St.Cera Co., Ltd. Launches Innovative Alumina Ceramic Pin for Precision ManufacturingSt.Cera Co., Ltd. is proud to announce the launch of its latest product, the Alumina Ceramic Pin. This innovative product is set to revolutionize the precision manufacturing industry with its exceptional durability, high temperature resistance, and superior performance.St.Cera Co., Ltd. is a private high-tech enterprise specializing in precision ceramic manufacturing. The company has a team of top-ranking experts and engineers in precision ceramic manufacturing. Their core competencies lie in research and development, manufacturing, and marketing of precision ceramic parts. With their dedication to innovation and excellence, St.Cera Co., Ltd. has become a leading provider of high-quality ceramic components for a wide range of industries, including automotive, aerospace, electronics, and medical devices.The Alumina Ceramic Pin is the latest addition to St.Cera Co., Ltd.'s extensive product lineup. Made from high-purity alumina ceramic, this pin offers exceptional performance and reliability in the most demanding manufacturing environments. Its outstanding hardness, wear resistance, and thermal stability make it the ideal choice for precision machining, inspection, and assembly applications.One of the key advantages of the Alumina Ceramic Pin is its exceptional durability. Unlike traditional metal pins, which are prone to wear and deformation, the Alumina Ceramic Pin maintains its shape and dimension over prolonged use, ensuring consistent and reliable performance. This not only reduces downtime for replacement and maintenance but also contributes to overall cost savings for manufacturers.In addition to its durability, the Alumina Ceramic Pin also offers superior thermal stability, making it suitable for high-temperature manufacturing processes. With a high melting point and excellent thermal conductivity, this pin can withstand extreme heat without compromising its performance, making it an ideal choice for applications such as metal casting, soldering, and heat treatment.Furthermore, the Alumina Ceramic Pin exhibits excellent chemical resistance, making it suitable for use in corrosive or abrasive manufacturing environments. Its inert nature ensures compatibility with a wide range of chemicals and solvents, making it a versatile and reliable tool for precision manufacturing processes.St.Cera Co., Ltd. is confident that the Alumina Ceramic Pin will set a new standard for precision manufacturing, enabling companies to improve efficiency and productivity while maintaining the highest quality standards. This innovative product reflects the company's commitment to providing cutting-edge solutions to meet the evolving needs of the industry."We are thrilled to introduce the Alumina Ceramic Pin to the market," said a spokesperson from St.Cera Co., Ltd. "Our team has worked tirelessly to develop a product that addresses the challenges faced by manufacturers in their pursuit of precision and reliability. We believe that the Alumina Ceramic Pin will offer significant benefits to our customers and contribute to the advancement of the manufacturing industry as a whole."With its unparalleled performance, durability, and thermal stability, the Alumina Ceramic Pin is poised to become an essential tool for precision machining and manufacturing processes. As St.Cera Co., Ltd. continues to push the boundaries of ceramic technology, the company remains dedicated to providing innovative solutions that empower manufacturers to achieve their goals with confidence and precision.For more information about the Alumina Ceramic Pin and other precision ceramic products from St.Cera Co., Ltd., please visit their website or contact their sales team directly.

Unique custom ceramic c-shape ring for personalized style

St.Cera Co., Ltd., a private high-tech enterprise specializing in precision ceramic manufacturing, has recently launched a new product, the Custom Ceramic C-Shape Ring. This innovative product is set to revolutionize the industry with its high quality and precision engineering.St.Cera Co., Ltd. is known for its team of top-ranking experts and engineers in precision ceramic manufacturing. The company's core competencies lie in research and development, manufacturing, and marketing of precision ceramic parts. The Custom Ceramic C-Shape Ring is a testament to the company's commitment to excellence and innovation in the industry.The Custom Ceramic C-Shape Ring is a versatile and durable product that is designed to meet the needs of a wide range of industries. The ring is made from high-quality ceramic material, which offers a number of advantages over traditional metal rings. Ceramic is known for its exceptional hardness, wear resistance, and corrosion resistance, making it an ideal material for a variety of applications.The Custom Ceramic C-Shape Ring is also designed to be highly customizable, allowing for a wide range of sizes, shapes, and designs to meet the specific needs of each customer. This level of customization sets the product apart from others on the market, making it a valuable addition to any manufacturing process.In addition to its exceptional durability and customization, the Custom Ceramic C-Shape Ring also offers superior performance in a variety of applications. The ceramic material used in the ring is also highly resistant to extreme temperatures, making it suitable for use in a wide range of environments. This makes the product an ideal choice for industries such as aerospace, automotive, medical, and semiconductor manufacturing.The launch of the Custom Ceramic C-Shape Ring is a significant milestone for St.Cera Co., Ltd. The company's dedication to precision engineering and innovation has resulted in a product that is set to make a lasting impact on the industry. With its exceptional quality and versatility, the ring is expected to be in high demand from a wide range of customers."We are excited to introduce the Custom Ceramic C-Shape Ring to the market," said a spokesperson for St.Cera Co., Ltd. "We believe that this product will set a new standard for precision engineering and performance in the industry. We are confident that our customers will be impressed with the quality and versatility of this innovative product."The launch of the Custom Ceramic C-Shape Ring is just the latest example of St.Cera Co., Ltd.'s commitment to excellence and innovation. The company has a proven track record of delivering high-quality precision ceramic parts to customers around the world. With its team of top-ranking experts and engineers, the company is well-positioned to continue leading the industry in precision ceramic manufacturing.In conclusion, the launch of the Custom Ceramic C-Shape Ring is a significant development for St.Cera Co., Ltd. The product's exceptional quality, versatility, and performance make it a valuable addition to the company's portfolio of precision ceramic parts. As the company continues to innovate and push the boundaries of the industry, the Custom Ceramic C-Shape Ring is set to make a lasting impact on the market.

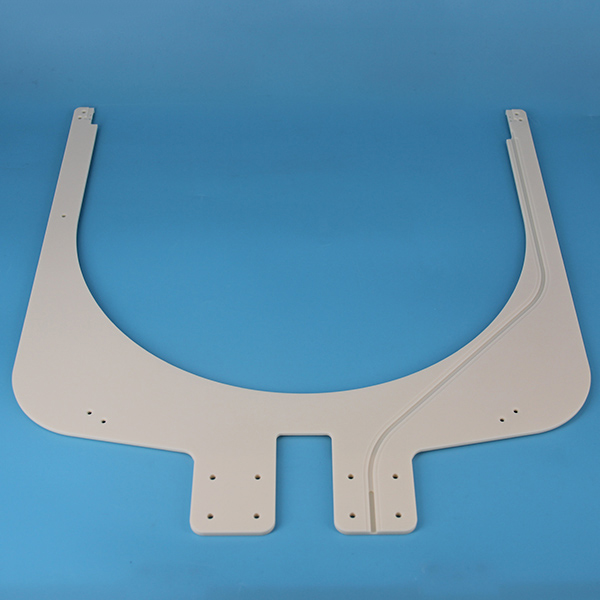

Advanced Ceramic End Effector for Industrial Applications

Sic Ceramic End Effector Increases Productivity for Manufacturing Company{Company} is excited to announce the launch of their new Sic Ceramic End Effector, designed to improve efficiency and productivity in manufacturing processes. This innovative tool promises to revolutionize the way the company handles their production line, and ultimately lead to cost savings and increased output.The Sic Ceramic End Effector is a state-of-the-art device that has been developed to handle the most demanding tasks in manufacturing. Its high-quality ceramic construction provides exceptional durability, thermal stability, and resistance to wear and tear, ensuring a longer lifespan and reduced need for replacement. This means that the company can expect significant cost savings in the long run, as they will not have to invest in frequent replacements or repairs of their end effectors.In addition to its durability, the Sic Ceramic End Effector has been designed with precision and accuracy in mind. Its advanced engineering allows for smooth and reliable operation, ensuring that it can handle even the most delicate and intricate tasks with ease. This level of precision is crucial for the company's manufacturing processes, as it will help to minimize errors and improve the overall quality of their products.One of the key benefits of the Sic Ceramic End Effector is its ability to withstand high temperatures, making it suitable for use in a wide range of manufacturing applications. This versatility means that the company can utilize the end effector in various processes, without having to worry about it being damaged or compromised by extreme heat. This will ultimately lead to greater flexibility and efficiency in their production line, as they will be able to use the Sic Ceramic End Effector in a variety of settings.The introduction of the Sic Ceramic End Effector aligns with {Company}'s commitment to innovation and excellence in manufacturing. By incorporating cutting-edge technology into their operations, they are able to stay ahead of the competition and maintain their position as a leader in the industry. The company's investment in this new end effector demonstrates their dedication to improving their processes and delivering the highest quality products to their customers.Furthermore, the Sic Ceramic End Effector is a testament to {Company}'s focus on sustainability and environmental responsibility. The use of ceramic materials not only provides superior performance, but also reduces the company's reliance on traditional materials that may have a greater impact on the environment. This aligns with their commitment to reducing their carbon footprint and minimizing waste, demonstrating their dedication to creating a more sustainable future.The introduction of the Sic Ceramic End Effector has already had a significant impact on {Company}'s operations. Preliminary testing has shown that the end effector has improved overall efficiency and productivity, leading to a noticeable increase in output. This has not only helped the company to meet their current production targets, but has also allowed them to explore new opportunities for growth and expansion.In conclusion, the introduction of the Sic Ceramic End Effector marks an important milestone for {Company}. By investing in this innovative technology, they are demonstrating their commitment to excellence, sustainability, and continuous improvement. The new end effector has the potential to revolutionize the way the company handles their manufacturing processes, leading to cost savings, improved quality, and increased productivity. As they continue to integrate this new tool into their operations, {Company} is poised to achieve even greater success and maintain their position as a leader in the industry.

High-Quality Ceramic Vacuum Chuck for Enhanced Industrial Performance

St.Cera Co., Ltd. Unveils New Ceramic Vacuum Chuck for Precision ManufacturingSt.Cera Co., Ltd. has announced the launch of a new ceramic vacuum chuck, designed to meet the needs of precision manufacturing. The company, known for its expertise in precision ceramic manufacturing, has developed the vacuum chuck to cater to the growing demand for high-quality, reliable solutions in the industry.The ceramic vacuum chuck, which has been developed by a team of top-ranking experts and engineers at St.Cera Co., Ltd., is set to revolutionize the precision manufacturing sector. With a strong focus on research and development, manufacturing, and marketing of precision ceramic parts, the company has once again demonstrated its commitment to innovation and excellence.Speaking about the new product, a spokesperson for St.Cera Co., Ltd. said, "We are thrilled to introduce our latest innovation to the precision manufacturing industry. The ceramic vacuum chuck is a result of extensive research and development, aimed at providing our customers with a high-quality solution that meets their specific needs. We believe that this product will set new standards in precision manufacturing and offer unmatched performance and reliability."The ceramic vacuum chuck boasts a number of features that set it apart from other solutions currently available in the market. Its high-precision design ensures superior grip and stability, allowing for precise and efficient manufacturing processes. The vacuum chuck is also highly durable, thanks to its use of high-quality ceramics, and is designed to withstand the rigors of continuous use in demanding manufacturing environments.In addition to its exceptional performance, the ceramic vacuum chuck is also designed with ease of use in mind. Its user-friendly interface and intuitive controls make it simple to operate, enabling manufacturers to streamline their processes and improve overall productivity. This combination of cutting-edge technology and user-friendly design makes the vacuum chuck a valuable addition to any precision manufacturing operation.The launch of the ceramic vacuum chuck is a significant milestone for St.Cera Co., Ltd., further cementing the company's position as a leader in the precision ceramic manufacturing industry. With its strong focus on innovation and excellence, the company has established a reputation for delivering high-quality solutions that meet the evolving needs of its customers.As part of its commitment to customer satisfaction, St.Cera Co., Ltd. is offering comprehensive support and after-sales service for the ceramic vacuum chuck. This includes expert guidance on installation and operation, as well as ongoing maintenance and technical support to ensure that customers can maximize the potential of their investment.In conclusion, the launch of the ceramic vacuum chuck represents an exciting development for the precision manufacturing industry. With its advanced technology, superior performance, and user-friendly design, the vacuum chuck is set to make a significant impact on the sector, providing manufacturers with a reliable and efficient solution for their precision manufacturing needs. St.Cera Co., Ltd. continues to lead the way in precision ceramic manufacturing, and the introduction of the ceramic vacuum chuck is yet another testament to the company's commitment to innovation and excellence.

Durable Zirconia Ceramic Pipes: A Strong Choice for Industrial Use

St.Cera Co., Ltd. Introduces Zirconia Ceramic Pipe for Precision ApplicationsSt.Cera Co., Ltd., a leading private high-tech enterprise specializing in precision ceramic manufacturing, has recently introduced a new product to their precision ceramic parts lineup - the Zirconia Ceramic Pipe. This innovative product is set to revolutionize the way precision applications are conducted in various industries.The Zirconia Ceramic Pipe is a cutting-edge solution that offers unparalleled performance and durability. It is designed to withstand high temperatures, corrosive chemicals, and extreme mechanical stress, making it the ideal choice for demanding precision applications.With a team of top-ranking experts and engineers in precision ceramic manufacturing, St.Cera Co., Ltd. has leveraged their core competencies in research and development to create a product that meets the highest standards of quality and reliability. The Zirconia Ceramic Pipe is the result of years of dedication to innovation and excellence in ceramic manufacturing."We are thrilled to introduce the Zirconia Ceramic Pipe to the market," said a spokesperson for St.Cera Co., Ltd. "This product represents a significant advancement in precision ceramic technology, and we believe it will have a profound impact on various industries that rely on high-performance ceramic components."One of the key features of the Zirconia Ceramic Pipe is its exceptional thermal insulation properties. This makes it well-suited for applications where heat resistance is critical, such as in the aerospace, automotive, and semiconductor industries. Additionally, its resistance to corrosion and wear make it a reliable choice for harsh environments, including chemical processing plants and oil and gas refineries.Furthermore, the Zirconia Ceramic Pipe offers superior mechanical strength, allowing it to withstand heavy loads and high levels of stress without compromising its integrity. This makes it a versatile solution for a wide range of precision applications, including but not limited to, fluid handling, pipe lining, and structural components.In addition to its exceptional performance characteristics, the Zirconia Ceramic Pipe is also lightweight and easy to install, making it a cost-effective solution for businesses looking to improve their operational efficiency.St.Cera Co., Ltd. has also prioritized environmental sustainability in the manufacturing of the Zirconia Ceramic Pipe. The use of zirconia, a naturally occurring material, ensures that the product is eco-friendly and in line with modern sustainability initiatives.The introduction of the Zirconia Ceramic Pipe is a testament to St.Cera Co., Ltd.'s commitment to providing cutting-edge solutions to their customers. With a strong emphasis on customer satisfaction and a dedication to continuous improvement, the company has positioned itself as a leader in the precision ceramic manufacturing industry."We are confident that the Zirconia Ceramic Pipe will set a new standard for precision ceramic components," said the spokesperson. "We are committed to supporting our customers in achieving their goals and are excited to see the positive impact that this product will have on their operations."As industries continue to demand high-performance materials for their precision applications, the Zirconia Ceramic Pipe from St.Cera Co., Ltd. is poised to become a game-changing solution. Its unrivaled combination of thermal insulation, corrosion resistance, mechanical strength, and environmental sustainability make it a product of choice for businesses looking to elevate their performance and reliability.St.Cera Co., Ltd. invites interested parties to learn more about the Zirconia Ceramic Pipe and explore how it can benefit their specific applications. With a track record of excellence and innovation, the company is well-positioned to provide reliable and high-quality solutions to meet the evolving needs of the precision ceramic industry.

Durable and Precise Ceramic Laser Nozzles for High-Quality Manufacturing

High-Quality Ceramic Laser Nozzle Enhances Precision and DurabilityWhen it comes to laser cutting and welding, having the right equipment can make all the difference in the quality and efficiency of the process. That's why the introduction of a high-quality ceramic laser nozzle by [Company Name] has been making waves in the industry. This innovative nozzle is designed to provide unparalleled precision and durability, making it a must-have tool for any professional in the field.[Company Name] is a leading manufacturer of laser cutting and welding equipment, known for its commitment to excellence and innovation. The company has a long history of producing high-quality products that meet the demands of the most challenging applications. With a team of dedicated engineers and designers, [Company Name] is constantly working to develop new and improved solutions that push the boundaries of what is possible in laser technology.The new high-quality ceramic laser nozzle is a perfect example of [Company Name]'s dedication to innovation. Made from advanced ceramic materials, this nozzle is designed to withstand the high temperatures and pressures that are typical in laser cutting and welding applications. This makes it highly durable and reliable, even in the most demanding environments.In addition to its durability, the ceramic material of the nozzle also offers exceptional thermal conductivity, allowing for more efficient heat dissipation during the laser cutting and welding process. This helps to minimize the risk of overheating and ensures a consistent performance over time.But perhaps the most impressive feature of the high-quality ceramic laser nozzle is its precision. The nozzle is designed to produce a highly focused and stable laser beam, enabling users to achieve incredibly precise cuts and welds with minimal kerf and heat-affected zones. This level of precision is crucial in many industries, where the quality of the finished product depends on the accuracy of the laser cutting and welding process.Furthermore, the ceramic material used in the nozzle is non-reactive, meaning that it does not interact with the laser beam or the materials being processed. This helps to prevent contamination and maintain the purity of the final product, making the high-quality ceramic laser nozzle a great choice for applications where cleanliness and accuracy are paramount.The high-quality ceramic laser nozzle is compatible with a wide range of laser cutting and welding systems, and it can be easily integrated into existing equipment. This makes it a versatile and cost-effective solution for professionals looking to upgrade their capabilities without having to invest in entirely new machinery.With the introduction of the high-quality ceramic laser nozzle, [Company Name] is once again demonstrating its commitment to providing cutting-edge solutions for the laser cutting and welding industry. This innovative nozzle is poised to set a new standard for precision and durability, and it is sure to be a game-changer for professionals who rely on laser technology to deliver exceptional results.In conclusion, the new high-quality ceramic laser nozzle from [Company Name] is an exciting development that promises to revolutionize the laser cutting and welding industry. With its exceptional precision and durability, this innovative nozzle is set to become an essential tool for professionals who demand the best results from their laser equipment. As [Company Name] continues to push the boundaries of what is possible in laser technology, the future looks brighter than ever for the industry and its professionals.

Durable Ceramic Laser Nozzle for Precision Cutting and Welding

St.Cera Co., Ltd., a private high-tech enterprise specializing in precision ceramic manufacturing, has recently announced the launch of its innovative Ceramic Laser Nozzle. With a team of top-ranking experts and engineers in precision ceramic manufacturing, the company has solidified its position as a leader in the industry.The Ceramic Laser Nozzle, which is free of brand name for competitive reasons, is a cutting-edge product designed to improve the efficiency and precision of laser cutting and welding processes. Made from high-quality precision ceramics, the nozzle exhibits exceptional heat resistance and durability, making it an ideal choice for industrial applications.The nozzle’s design and manufacturing process are a testament to St.Cera’s commitment to research and development in the precision ceramic industry. The company’s core competencies in precision ceramic manufacturing have been instrumental in the creation of this groundbreaking product. Through rigorous testing and refinement, St.Cera has successfully developed a nozzle that meets the stringent requirements of modern laser cutting and welding processes.St.Cera Co., Ltd. is renowned for its dedication to producing high-quality precision ceramic components that cater to a wide range of industries. With a focus on research, development, manufacturing, and marketing of precision ceramic parts, the company has established itself as a reliable partner for businesses seeking innovative solutions for their manufacturing needs.The Ceramic Laser Nozzle is a testament to St.Cera’s expertise and commitment to advancing the capabilities of precision ceramics in industrial applications. By leveraging the unique properties of ceramics, the company has been able to develop a product that offers superior performance and longevity compared to traditional metal nozzles.In addition to its exceptional heat resistance, the Ceramic Laser Nozzle exhibits excellent wear resistance, ensuring consistent performance over extended periods of use. This characteristic is particularly valuable for businesses looking to minimize downtime and maintenance costs associated with laser cutting and welding equipment.Moreover, the nozzle’s precision engineering ensures consistent and reliable operation, allowing businesses to achieve higher levels of accuracy and efficiency in their manufacturing processes. By reducing the need for frequent maintenance and replacement, the Ceramic Laser Nozzle offers a cost-effective solution for businesses seeking to optimize their operations.With its innovative approach to precision ceramic manufacturing, St.Cera Co., Ltd. has positioned itself as a leading provider of advanced ceramic components for industrial applications. The company’s dedication to research and development has enabled it to push the boundaries of what is possible with ceramics, resulting in the creation of the Ceramic Laser Nozzle.As businesses continue to seek ways to improve the efficiency and reliability of their manufacturing processes, the Ceramic Laser Nozzle represents a significant advancement in the field of precision ceramic components. With its unrivaled heat resistance, durability, and precision engineering, the nozzle is poised to become an essential tool for businesses operating in the laser cutting and welding industries.St.Cera’s commitment to innovation and excellence has made it a trusted partner for businesses seeking high-quality precision ceramic components. The launch of the Ceramic Laser Nozzle further solidifies the company’s reputation as a leader in the industry and demonstrates its ongoing dedication to advancing the capabilities of precision ceramics in industrial settings.Overall, the introduction of the Ceramic Laser Nozzle represents a significant milestone for St.Cera Co., Ltd. and a major advancement for the precision ceramic manufacturing industry as a whole. With its superior performance and reliability, the nozzle is set to revolutionize the way businesses approach laser cutting and welding processes, offering a compelling alternative to traditional metal components.As St.Cera continues to push the boundaries of what is possible with precision ceramics, businesses can expect to benefit from a new generation of innovative and high-performance products that will help them achieve greater efficiency and reliability in their manufacturing operations. The Ceramic Laser Nozzle is just the beginning of what promises to be an exciting journey for St.Cera and the future of precision ceramic components.

Discover the Latest Innovations in Ceramic Tube Technology

Beijing, China - In a bid to revolutionize the ceramic tube industry, a leading company has recently introduced a groundbreaking product that is set to redefine the way we use and perceive ceramic tubes. The new product, Beo Ceramic Tube, promises to provide unparalleled performance and durability, making it a game-changer in various industrial applications.The Beo Ceramic Tube is the latest innovation from the renowned company, which has been at the forefront of producing high-quality ceramic products for over two decades. With a strong commitment to technological advancement and product development, the company has consistently pushed the boundaries of what is possible with ceramic materials. The introduction of the Beo Ceramic Tube is yet another testament to their dedication to innovation and excellence.One of the key features of the Beo Ceramic Tube is its exceptional strength and durability. Made from high-grade ceramic materials, the tube is capable of withstanding extreme temperatures and harsh operating conditions, making it ideal for a wide range of industrial applications. Whether it is used in the metallurgical industry, chemical plants, or power generation facilities, the Beo Ceramic Tube is designed to deliver superior performance and reliability.Furthermore, the Beo Ceramic Tube offers excellent thermal insulation properties, making it an ideal choice for applications that require high-temperature resistance. This not only enhances the efficiency of industrial processes but also helps in reducing energy consumption, making it an environmentally friendly option. Additionally, the tube's resistance to corrosion and chemical attacks further adds to its longevity, making it a cost-effective solution for various industrial needs.In addition to its exceptional physical properties, the Beo Ceramic Tube is also designed for ease of installation and maintenance. Its lightweight and easy-to-handle design make it convenient for technicians to work with, saving both time and effort during installation and replacement. This, coupled with its long service life, makes it a highly economical choice for industrial facilities looking to minimize downtime and maintenance costs.The company behind the Beo Ceramic Tube is committed to providing comprehensive support to its customers. With a team of experienced engineers and technical experts, they offer personalized consulting services to help customers select the right ceramic tube solutions for their specific needs. This customer-centric approach has earned them a reputation for being a trusted partner in the industry, and the introduction of the Beo Ceramic Tube is poised to further solidify their position as a leading provider of ceramic products.The Beo Ceramic Tube has already garnered attention and positive feedback from industry professionals who have had the opportunity to test its capabilities. Many have praised its exceptional performance and durability, noting that it has exceeded their expectations and outperformed other ceramic tube options currently available in the market.With the introduction of the Beo Ceramic Tube, the company aims to set a new standard for ceramic tube technology and provide industrial customers with a reliable and high-performance solution that meets the demands of modern industrial applications. As the industry continues to evolve, the company remains committed to pushing the boundaries of ceramic material technology and delivering innovative solutions that address the evolving needs of its customers.In conclusion, the Beo Ceramic Tube represents a significant advancement in ceramic tube technology and is set to make a lasting impact on various industrial sectors. With its exceptional strength, durability, and thermal insulation properties, it is poised to become the go-to choice for industrial applications that require high-performance ceramic tubes. As the company continues to drive innovation and excellence in the industry, the Beo Ceramic Tube stands as a testament to their commitment to pushing the boundaries of what is possible with ceramic materials.

New Ceramic Pin Unveiled as Latest Innovation

St.Cera Co., Ltd. Introduces Innovative Beo Ceramic PinSt.Cera Co., Ltd. is making waves in the precision ceramic manufacturing industry with its latest innovation, the Beo Ceramic Pin. The Beo Ceramic Pin is a game-changer in the field of precision ceramic parts, offering unparalleled performance and durability.St.Cera Co., Ltd. is a private high-tech enterprise specializing in precision ceramic manufacturing. The company has a team of top-ranking experts and engineers in precision ceramic manufacturing. Their core competencies lie in research and development, manufacturing, and marketing of precision ceramic parts. Their dedication to innovation and quality has positioned them as a leader in the industry.The Beo Ceramic Pin is the latest testament to the company's commitment to excellence. It is designed to meet the evolving needs of industries that rely on precision ceramic parts for their operations. The pin is manufactured using the latest technologies and cutting-edge materials, ensuring superior performance and longevity.One of the key features of the Beo Ceramic Pin is its exceptional durability. Unlike traditional metal pins, the Beo Ceramic Pin is highly resistant to wear and corrosion, making it ideal for use in demanding industrial applications. Its superior thermal and electrical insulation properties further enhance its suitability for a wide range of uses.In addition to its durability, the Beo Ceramic Pin also offers unmatched precision. Its advanced manufacturing process ensures tight tolerances and consistent quality, making it the top choice for industries that require precise and reliable components. The pin's excellent dimensional stability and resistance to deformation further underscore its superiority.The Beo Ceramic Pin has already garnered attention from various industries, including electronics, aerospace, automotive, and medical. Its versatility and high performance make it a valuable asset for manufacturers looking to improve the quality and reliability of their products. Furthermore, its ability to withstand extreme conditions and harsh environments opens up new possibilities for applications in challenging settings.St.Cera Co., Ltd. is proud to introduce the Beo Ceramic Pin as part of its ongoing commitment to innovation and customer satisfaction. The company's dedication to research and development has enabled them to push the boundaries of precision ceramic manufacturing, setting new standards for quality and performance.The Beo Ceramic Pin is just one example of St.Cera Co., Ltd.'s ability to deliver groundbreaking solutions to the market. With a strong focus on technology and expertise, the company continues to lead the way in the development of advanced ceramic components that address the evolving needs of modern industries.The introduction of the Beo Ceramic Pin is a significant milestone for St.Cera Co., Ltd., and it reflects their relentless pursuit of excellence. The company's unwavering dedication to quality and innovation has solidified its reputation as a trusted partner for businesses seeking high-quality precision ceramic parts.Moving forward, St.Cera Co., Ltd. is poised to further expand its product portfolio and capabilities, ensuring that it remains at the forefront of the precision ceramic manufacturing industry. With a steadfast commitment to excellence, the company is well-positioned to continue driving progress and shaping the future of precision ceramic components.

Durable and Efficient Ceramic Vacuum Chuck for High-Quality Applications

St.Cera Co., Ltd., a private high-tech enterprise specializing in precision ceramic manufacturing, has recently launched a new high-quality Ceramic Vacuum Chuck that is set to revolutionize the industry. With a team of top-ranking experts and engineers in precision ceramic manufacturing, the company has consistently demonstrated its core competencies in research and development, manufacturing, and marketing of precision ceramic parts.The newly developed Ceramic Vacuum Chuck is designed to provide superior performance and reliability for a wide range of applications. The innovative design and high-quality materials used in its construction make it ideal for use in demanding manufacturing environments where precision and consistency are crucial.One of the key features of the Ceramic Vacuum Chuck is its exceptional flatness and parallelism, which significantly improves the accuracy and repeatability of machining and processing operations. This ensures that workpieces are held securely in place, leading to higher-quality finished products and reduced scrap rates.Another notable feature of the Ceramic Vacuum Chuck is its excellent thermal stability, which allows it to maintain its flatness and parallelism even under extreme temperature variations. This makes it well-suited for use in applications where thermal management is critical, such as in the semiconductor and electronics industries.Additionally, the Ceramic Vacuum Chuck is highly resistant to corrosion and wear, ensuring a long service life and minimal maintenance requirements. This not only reduces downtime and production costs but also contributes to a more sustainable and environmentally friendly manufacturing process.The innovative design of the Ceramic Vacuum Chuck also includes advanced vacuum technology that ensures a strong and consistent grip on the workpiece, without the need for additional clamping mechanisms. This not only simplifies the setup and operation of machining and processing equipment but also improves overall productivity and throughput.Furthermore, the Ceramic Vacuum Chuck is available in a variety of sizes and configurations to accommodate different machine types and workpiece dimensions. This versatility makes it a practical solution for a wide range of industries, including aerospace, automotive, medical, and many others.In a statement, the spokesperson for St.Cera Co., Ltd. expressed their confidence in the new Ceramic Vacuum Chuck, saying, "We are proud to introduce our latest innovation to the market. The Ceramic Vacuum Chuck represents the culmination of our extensive expertise and commitment to delivering high-quality precision ceramic solutions. We are confident that it will set a new standard for performance and reliability in the industry."The launch of the Ceramic Vacuum Chuck further solidifies St.Cera Co., Ltd.'s position as a leading provider of precision ceramic parts and solutions. With a strong focus on innovation and continuous improvement, the company remains dedicated to meeting the evolving needs of modern manufacturing and delivering value to its customers.In conclusion, the newly launched high-quality Ceramic Vacuum Chuck from St.Cera Co., Ltd. is poised to make a significant impact on the precision manufacturing industry. With its innovative design, exceptional performance, and versatility, it promises to enhance productivity, quality, and efficiency across a wide range of applications. As the industry continues to evolve, St.Cera Co., Ltd. remains at the forefront, driving innovation and setting new benchmarks for excellence in precision ceramic manufacturing.