Durable and High-Quality Quartz Tube for Various Applications

By:Admin

St.Cera Co., Ltd. is proud to announce the launch of a new product in their precision ceramic manufacturing line: High-Quality Quartz Tube. This innovative product is designed to meet the stringent demands of precision applications, offering customers unparalleled performance and reliability.

St.Cera Co., Ltd. is a private high-tech enterprise specializing in precision ceramic manufacturing. The company boasts a team of top-ranking experts and engineers in precision ceramic manufacturing, and their core competencies lie in research and development, manufacturing, and marketing of precision ceramic parts.

The new High-Quality Quartz Tube is the latest addition to St.Cera’s comprehensive range of precision ceramic products. This product has been engineered to provide exceptional thermal stability, high chemical purity, and outstanding optical transmission, making it a perfect solution for a wide range of precision applications.

From semiconductor manufacturing to laboratory equipment, the High-Quality Quartz Tube offers superior performance in demanding environments. Its high chemical purity ensures minimal contamination, while its exceptional thermal stability allows for consistent performance across a wide temperature range.

St.Cera Co., Ltd. is committed to delivering the highest quality products to their customers, and the High-Quality Quartz Tube is no exception. Each tube is meticulously manufactured using advanced production techniques and undergoes rigorous quality control measures to ensure it meets the company’s exacting standards.

The company’s dedication to quality is reflected in the performance of the High-Quality Quartz Tube, which has received overwhelmingly positive feedback from early adopters. Customers have praised its durability, reliability, and exceptional optical properties, making it a standout choice for precision applications.

In addition to its superior performance, the High-Quality Quartz Tube also benefits from St.Cera’s expertise in precision ceramic manufacturing. The company’s team of top-ranking experts and engineers have leveraged their extensive knowledge and experience to develop a product that sets a new standard for quality and performance.

St.Cera Co., Ltd. is committed to supporting their customers with exceptional service and technical expertise. The company’s dedicated team is on hand to provide expert guidance and support, ensuring customers are able to make the most of the High-Quality Quartz Tube in their specific applications.

With the introduction of the High-Quality Quartz Tube, St.Cera Co., Ltd. continues to solidify its position as a leading provider of precision ceramic products. The company’s commitment to innovation, quality, and customer satisfaction sets them apart in the industry, and the new product is a testament to their ongoing dedication to excellence.

“We are thrilled to introduce the High-Quality Quartz Tube to our customers,” said a spokesperson for St.Cera Co., Ltd. “This product represents the culmination of our expertise and dedication to delivering the best possible solutions for precision applications. We are confident it will exceed our customers’ expectations and set a new standard for performance and reliability.”

As St.Cera Co., Ltd. continues to expand their product line and drive innovation in precision ceramic manufacturing, the introduction of the High-Quality Quartz Tube marks an exciting milestone for the company and its customers. With its exceptional performance and unwavering commitment to quality, this product is set to become an indispensable solution for precision applications across a wide range of industries.

To learn more about the High-Quality Quartz Tube and St.Cera Co., Ltd.’s comprehensive range of precision ceramic products, please visit their website or contact their team directly for personalized assistance and guidance.

Company News & Blog

Durable and High-Quality Quartz Tube for Various Applications

St.Cera Co., Ltd. Introduces High-Quality Quartz Tube for Precision ApplicationsSt.Cera Co., Ltd. is proud to announce the launch of a new product in their precision ceramic manufacturing line: High-Quality Quartz Tube. This innovative product is designed to meet the stringent demands of precision applications, offering customers unparalleled performance and reliability.St.Cera Co., Ltd. is a private high-tech enterprise specializing in precision ceramic manufacturing. The company boasts a team of top-ranking experts and engineers in precision ceramic manufacturing, and their core competencies lie in research and development, manufacturing, and marketing of precision ceramic parts.The new High-Quality Quartz Tube is the latest addition to St.Cera’s comprehensive range of precision ceramic products. This product has been engineered to provide exceptional thermal stability, high chemical purity, and outstanding optical transmission, making it a perfect solution for a wide range of precision applications.From semiconductor manufacturing to laboratory equipment, the High-Quality Quartz Tube offers superior performance in demanding environments. Its high chemical purity ensures minimal contamination, while its exceptional thermal stability allows for consistent performance across a wide temperature range.St.Cera Co., Ltd. is committed to delivering the highest quality products to their customers, and the High-Quality Quartz Tube is no exception. Each tube is meticulously manufactured using advanced production techniques and undergoes rigorous quality control measures to ensure it meets the company’s exacting standards.The company’s dedication to quality is reflected in the performance of the High-Quality Quartz Tube, which has received overwhelmingly positive feedback from early adopters. Customers have praised its durability, reliability, and exceptional optical properties, making it a standout choice for precision applications.In addition to its superior performance, the High-Quality Quartz Tube also benefits from St.Cera’s expertise in precision ceramic manufacturing. The company’s team of top-ranking experts and engineers have leveraged their extensive knowledge and experience to develop a product that sets a new standard for quality and performance.St.Cera Co., Ltd. is committed to supporting their customers with exceptional service and technical expertise. The company’s dedicated team is on hand to provide expert guidance and support, ensuring customers are able to make the most of the High-Quality Quartz Tube in their specific applications.With the introduction of the High-Quality Quartz Tube, St.Cera Co., Ltd. continues to solidify its position as a leading provider of precision ceramic products. The company’s commitment to innovation, quality, and customer satisfaction sets them apart in the industry, and the new product is a testament to their ongoing dedication to excellence.“We are thrilled to introduce the High-Quality Quartz Tube to our customers,” said a spokesperson for St.Cera Co., Ltd. “This product represents the culmination of our expertise and dedication to delivering the best possible solutions for precision applications. We are confident it will exceed our customers’ expectations and set a new standard for performance and reliability.”As St.Cera Co., Ltd. continues to expand their product line and drive innovation in precision ceramic manufacturing, the introduction of the High-Quality Quartz Tube marks an exciting milestone for the company and its customers. With its exceptional performance and unwavering commitment to quality, this product is set to become an indispensable solution for precision applications across a wide range of industries.To learn more about the High-Quality Quartz Tube and St.Cera Co., Ltd.’s comprehensive range of precision ceramic products, please visit their website or contact their team directly for personalized assistance and guidance.

Durable and high-quality sapphire cylinder for multiple applications

St.Cera Co., Ltd., a private high-tech enterprise specializing in precision ceramic manufacturing, has recently announced the development of a high-quality sapphire cylinder that is expected to revolutionize various industries. The company’s team of top-ranking experts and engineers has been instrumental in the research and development, manufacturing, and marketing of this groundbreaking product.Sapphire is a unique material known for its exceptional hardness and durability, making it an ideal choice for various applications requiring high-performance components. St.Cera Co., Ltd. has leveraged its expertise in precision ceramic manufacturing to create a sapphire cylinder of unparalleled quality. This innovative product is expected to find widespread use in industries such as aerospace, defense, medical, and electronics.The sapphire cylinder developed by St.Cera Co., Ltd. boasts superior mechanical and thermal properties, making it highly resistant to wear and corrosion. This level of durability makes it an excellent choice for demanding applications where traditional materials may fall short. Additionally, sapphire’s optical clarity and high optical transmission make it an ideal material for use in high-precision optical and laser systems.With a focus on producing high-quality precision ceramic parts, St.Cera Co., Ltd. has positioned itself as a leader in the industry. The company’s commitment to research and development has allowed it to stay ahead of the curve, offering innovative solutions to meet the evolving needs of its customers. The sapphire cylinder is the latest example of the company’s dedication to pushing the boundaries of what is possible in precision ceramic manufacturing.In addition to its impressive material properties, the sapphire cylinder manufactured by St.Cera Co., Ltd. also benefits from the company’s advanced manufacturing processes. By employing state-of-the-art equipment and techniques, the company is able to produce sapphire cylinders with precise dimensions and superior surface finishes. This level of craftsmanship is essential for ensuring the performance and reliability of the product in various applications.The launch of the sapphire cylinder represents an important milestone for St.Cera Co., Ltd. as it continues to expand its product offerings and reach new markets. The company’s strong foothold in precision ceramic manufacturing, combined with its dedication to delivering high-quality solutions, positions it as a trusted partner for industries seeking advanced materials and components. The sapphire cylinder is expected to further enhance the company’s reputation as a leading provider of precision ceramic parts.St.Cera Co., Ltd. is no stranger to innovation, having established itself as a pioneer in the field of precision ceramic manufacturing. The company’s ongoing investment in research and development ensures that it remains at the forefront of technological advancements, allowing it to meet the most demanding requirements of its customers. The sapphire cylinder serves as a testament to the company’s ability to push the boundaries of what is achievable in precision ceramic manufacturing.As industries continue to demand high-performance materials and components, St.Cera Co., Ltd. is well-positioned to meet these needs with its high-quality sapphire cylinder. The company’s unwavering commitment to excellence and its track record of delivering innovative solutions make it a preferred partner for a wide range of applications. With the launch of the sapphire cylinder, St.Cera Co., Ltd. is set to make a significant impact on industries that rely on precision ceramic parts.In conclusion, the development of the high-quality sapphire cylinder by St.Cera Co., Ltd. represents a significant advancement in precision ceramic manufacturing. The company’s expertise and dedication to producing exceptional solutions have culminated in a product that is poised to revolutionize various industries. With its impressive material properties and advanced manufacturing processes, the sapphire cylinder is set to meet the rigorous demands of aerospace, defense, medical, and electronics applications. St.Cera Co., Ltd. continues to set the standard for precision ceramic manufacturing, and the launch of the sapphire cylinder further solidifies its position as a leading provider of high-quality solutions.

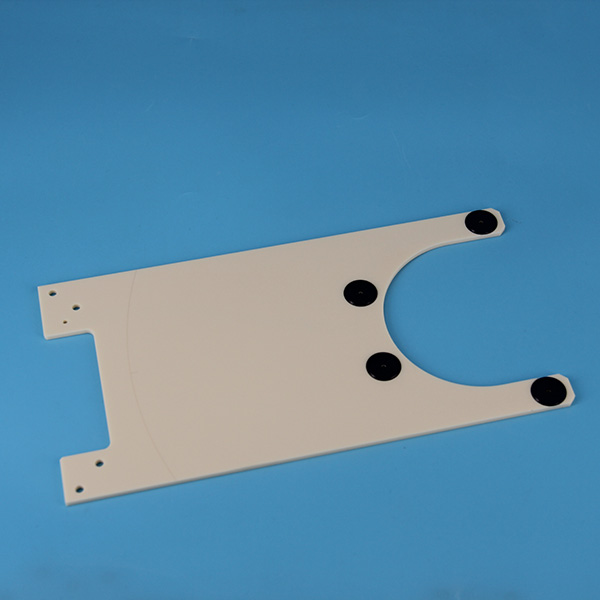

Durable and Customizable Ceramic Sheet for Your Project Needs

Custom Ceramic Sheet Innovations: St.Cera Co., Ltd. Leads the Way in Precision Ceramic ManufacturingSt.Cera Co., Ltd. is making waves in the world of precision ceramic manufacturing with their latest innovative product, the Custom Ceramic Sheet. This private high-tech enterprise has been a pioneer in the industry, specializing in precision ceramic manufacturing for a wide range of applications.The Custom Ceramic Sheet is the latest addition to St.Cera's impressive line of products, and it is already creating a buzz in the market. This advanced ceramic material offers unparalleled performance and versatility, making it ideal for a variety of uses across different industries. The Custom Ceramic Sheet is meticulously engineered and designed by St.Cera's team of top-ranking experts and engineers, who are renowned for their expertise and innovation in precision ceramic manufacturing.Mr. Zhang, the CEO of St.Cera Co., Ltd., expressed his excitement about the launch of the Custom Ceramic Sheet, saying, "We are proud to introduce the Custom Ceramic Sheet to the market. This innovative product is a testament to our commitment to excellence and our passion for pushing the boundaries of precision ceramic manufacturing. We believe that the Custom Ceramic Sheet will set a new industry standard and open up exciting possibilities for our customers."St.Cera's Custom Ceramic Sheet is a result of years of research and development, backed by the company's unwavering dedication to quality and precision. The company's core competencies lie in research and development, manufacturing, and marketing of precision ceramic parts, and the Custom Ceramic Sheet is a shining example of their expertise in these areas.One of the key features of the Custom Ceramic Sheet is its customizable nature, which allows customers to tailor the material to their specific requirements. Whether it's for use in electronics, semiconductor processing, medical equipment, or aerospace technology, the Custom Ceramic Sheet can be engineered to meet the most demanding specifications. Its exceptional thermal stability, high strength, and superior electrical insulation make it a standout choice for various high-tech applications.In addition to its outstanding performance attributes, the Custom Ceramic Sheet also offers a longer lifespan and greater durability compared to traditional materials. This durability is further enhanced by its resistance to corrosion, wear, and extreme temperatures, making it a reliable option for critical components in demanding environments.Furthermore, the Custom Ceramic Sheet boasts excellent dimensional stability and tight tolerances, ensuring consistency in quality and performance. This level of precision is a hallmark of St.Cera's manufacturing processes, which are underpinned by state-of-the-art technology and stringent quality control measures.St.Cera Co., Ltd.'s commitment to sustainable and environmentally-friendly manufacturing is also evident in the production of the Custom Ceramic Sheet. The company employs eco-friendly processes and materials, reducing waste and minimizing the environmental impact of their operations. This aligns with St.Cera's vision of being a responsible corporate citizen and contributing to a greener and healthier planet.The introduction of the Custom Ceramic Sheet reinforces St.Cera's position as a trailblazer in precision ceramic manufacturing. The company's dedication to innovation and customer satisfaction has earned them a strong reputation in the industry, and the Custom Ceramic Sheet is poised to further enhance their standing.As demand for high-performance materials continues to grow across various sectors, the Custom Ceramic Sheet is expected to find wide-ranging applications and drive advancements in technology and engineering. Its versatility, reliability, and exceptional properties will undoubtedly make it a sought-after solution for companies seeking cutting-edge materials for their products and systems.In conclusion, St.Cera Co., Ltd.'s launch of the Custom Ceramic Sheet marks a significant milestone in the field of precision ceramic manufacturing. With its remarkable performance attributes, customizable nature, and environmental sustainability, the Custom Ceramic Sheet is set to make a lasting impact in diverse industries. St.Cera's relentless pursuit of excellence and their unwavering commitment to quality have once again placed them at the forefront of innovation, setting new benchmarks for precision ceramic manufacturing.

High-quality Ceramic Finger Factory for Custom Bernoulli Products

St.Cera Co., Ltd. is making waves in the precision ceramic manufacturing industry with the launch of their new custom Bernoulli ceramic finger factory. The company, a private high-tech enterprise, has been at the forefront of precision ceramic manufacturing, and their latest innovation is set to revolutionize the industry.The custom Bernoulli ceramic finger factory is a testament to St.Cera's dedication to research and development, manufacturing, and marketing of precision ceramic parts. The company has assembled a team of top-ranking experts and engineers who have worked tirelessly to bring this cutting-edge technology to the market.The factory is equipped with state-of-the-art machinery and equipment, allowing St.Cera to produce high-quality custom Bernoulli ceramic fingers with unparalleled precision and accuracy. This breakthrough in ceramic manufacturing has the potential to enhance the performance of a wide range of products, from industrial machinery to consumer electronics.One of the key advantages of the custom Bernoulli ceramic fingers manufactured at St.Cera's factory is their exceptional durability and thermal stability. These properties make them an ideal choice for applications that require reliable and long-lasting components, such as in the aerospace and automotive industries.In addition to their superior physical properties, the custom Bernoulli ceramic fingers boast excellent resistance to corrosion and wear, making them a cost-effective solution for companies seeking to improve the longevity of their products.With the launch of the custom Bernoulli ceramic finger factory, St.Cera is positioning itself as a leader in the precision ceramic manufacturing industry. The company's commitment to innovation and excellence has earned them a strong reputation among their peers and customers.The custom Bernoulli ceramic fingers produced at the factory will be available for purchase by companies looking to enhance the performance and durability of their products. St.Cera's sales and marketing team is already working to spread the word about this groundbreaking technology, and the response from potential customers has been overwhelmingly positive.Industry experts have also taken notice of St.Cera's latest innovation, with many acknowledging the potential impact it could have on various sectors. The custom Bernoulli ceramic fingers have been hailed as a game-changer, and their introduction to the market is expected to shake up the competition.The launch of the custom Bernoulli ceramic finger factory is the latest milestone in St.Cera's journey to establish itself as a leading provider of precision ceramic parts. The company's unwavering dedication to quality and excellence has set them apart in the industry, and their latest offering is a testament to their commitment to pushing the boundaries of what is possible in ceramic manufacturing.St.Cera's custom Bernoulli ceramic fingers are set to make a significant impact on the industry, and their potential applications are vast. From improving the performance of industrial machinery to enhancing the durability of consumer electronics, the custom Bernoulli ceramic fingers have the potential to revolutionize the way companies approach product design and manufacturing.As St.Cera continues to gain recognition for their groundbreaking technology, the company is poised to usher in a new era of precision ceramic manufacturing. The custom Bernoulli ceramic fingers produced at their factory will undoubtedly leave a lasting impression on the industry, and St.Cera's dedication to innovation ensures that they will remain at the forefront of ceramic manufacturing for years to come.

Unique Ceramic Fork for Customization and Personalization

St.Cera Co., Ltd. unveils Custom Bernoulli Ceramic ForkSt.Cera Co., Ltd., a leading private high-tech enterprise specializing in precision ceramic manufacturing, has recently announced the launch of its latest innovation, the Custom Bernoulli Ceramic Fork. The company, which is renowned for its expertise in research and development, manufacturing, and marketing of precision ceramic parts, has once again demonstrated its commitment to pushing the boundaries of ceramic technology with this new product.The Custom Bernoulli Ceramic Fork is a testament to St.Cera's dedication to excellence and innovation in the field of precision ceramic manufacturing. With a team of top-ranking experts and engineers, the company has been at the forefront of developing cutting-edge ceramic products that offer superior performance, durability, and quality.The Bernoulli Ceramic Fork is named after the Swiss mathematician and physicist, Daniel Bernoulli, whose principle of fluid dynamics is the inspiration behind the design of this innovative product. The fork is crafted using the highest quality ceramic materials, ensuring exceptional strength, hardness, and resistance to wear and corrosion.One of the key features of the Custom Bernoulli Ceramic Fork is its unique design, which is optimized for precision and efficiency. The fork's ceramic construction allows for smooth and precise handling, making it ideal for use in a wide range of applications, including aerospace, medical devices, automotive engineering, and more.In addition to its exceptional performance, the Custom Bernoulli Ceramic Fork also offers significant advantages in terms of hygiene and safety. Ceramic materials are non-porous and resistant to bacteria, making them an ideal choice for applications where cleanliness and sterility are crucial. Furthermore, the fork's corrosion-resistant properties ensure that it remains in pristine condition even after prolonged use.The launch of the Custom Bernoulli Ceramic Fork underscores St.Cera's ongoing commitment to setting new standards in the precision ceramic manufacturing industry. By leveraging its expertise in materials science, engineering, and manufacturing, the company continues to develop innovative solutions that address the evolving needs of its customers in various sectors.Commenting on the launch of the Custom Bernoulli Ceramic Fork, a spokesperson for St.Cera Co., Ltd. said, "We are thrilled to introduce this groundbreaking product to the market. The Custom Bernoulli Ceramic Fork exemplifies our dedication to advancing ceramic technology and delivering exceptional quality to our customers. We believe that this product will set a new benchmark for precision and reliability in the industry."The announcement of the Custom Bernoulli Ceramic Fork has garnered significant attention from industry professionals, engineers, and researchers who recognize the potential of this innovative product to redefine standards in precision ceramic manufacturing. With its advanced design, superior performance, and robust construction, the Bernoulli Ceramic Fork is poised to make a significant impact in various sectors where precision and durability are paramount.As St.Cera Co., Ltd. continues to expand its presence in the global market, the launch of the Custom Bernoulli Ceramic Fork reaffirms the company's position as a leader in precision ceramic manufacturing. With its relentless focus on innovation, quality, and excellence, St.Cera is poised to shape the future of ceramic technology and set new benchmarks for performance and reliability in the industry.In conclusion, the introduction of the Custom Bernoulli Ceramic Fork is a testament to St.Cera's commitment to pushing the boundaries of ceramic technology and delivering exceptional quality to its customers. With its advanced design, superior performance, and robust construction, the Bernoulli Ceramic Fork is set to redefine standards in precision ceramic manufacturing and make a lasting impact in various industries. St.Cera Co., Ltd. continues to lead the way in advancing ceramic technology, and the launch of this innovative product reaffirms the company's position as a top-ranking expert in the field.

High-Quality Ceramic Pellets for Custom Applications

Custom Ceramic Pellets: Revolutionizing the Manufacturing IndustryIn today's rapidly evolving manufacturing industry, companies are constantly seeking ways to improve efficiency and quality while reducing costs. One innovative solution that has been making waves in the industry is custom ceramic pellets. These highly specialized pellets have been revolutionizing the way products are manufactured, offering a range of benefits that traditional materials simply cannot match.Custom ceramic pellets are engineered to provide a superior alternative to traditional materials such as metal, plastic, or even other types of ceramic. They are created through a meticulous process that involves precise blending of raw materials, advanced shaping techniques, and a high-temperature firing process. The end result is a product that exhibits exceptional strength, durability, and resistance to wear and corrosion.For companies seeking to improve their manufacturing processes, custom ceramic pellets offer several key advantages. One of the most significant benefits is their exceptional hardness and resistance to abrasion. This makes them an ideal choice for producing components that are subjected to high levels of wear and tear, such as cutting tools, bearings, and abrasive components.Furthermore, custom ceramic pellets offer unparalleled thermal and electrical insulation properties, making them an excellent choice for applications that involve extreme temperatures or high levels of electrical conductivity. This versatility makes them a highly sought-after material for a range of industrial applications, from electronics manufacturing to aerospace and defense.In addition to their superior physical properties, custom ceramic pellets also offer significant cost savings for manufacturers. By utilizing these pellets, companies can reduce the need for frequent maintenance and replacements, resulting in lower overall production costs and improved productivity. Furthermore, their lightweight nature can lead to reduced energy consumption, further contributing to cost savings and environmental sustainability.One company that has been at the forefront of the custom ceramic pellet revolution is {}. Specializing in the design and production of premium-quality ceramic materials, {} has been pioneering the development of custom ceramic pellets for a wide range of industrial applications. With a team of highly skilled engineers and state-of-the-art manufacturing facilities, {} is able to offer customized solutions that are tailored to each client's specific needs.The company's extensive experience and expertise in the field of ceramic engineering allows them to deliver superior quality products that consistently exceed industry standards. By working closely with their clients, {} is able to develop custom ceramic pellets that are perfectly suited to their unique requirements, resulting in improved performance, longevity, and overall cost-effectiveness.Furthermore, {} is committed to sustainability and environmental responsibility, ensuring that their manufacturing processes are as efficient and eco-friendly as possible. By utilizing advanced technologies and adhering to strict quality control measures, the company is able to minimize waste and energy consumption, while maximizing the performance and durability of their products.With an unwavering dedication to innovation and excellence, {} continues to set the bar for the custom ceramic pellet industry, providing manufacturers with a superior alternative to traditional materials. As the demand for high-performance, cost-effective materials continues to grow, custom ceramic pellets are poised to play a pivotal role in the future of manufacturing, and {} is well-positioned to lead the way.In conclusion, custom ceramic pellets are transforming the manufacturing industry, offering a range of benefits that are simply unmatched by traditional materials. With their exceptional strength, durability, and versatility, these pellets are becoming an invaluable asset for companies seeking to improve the quality and cost-effectiveness of their products. As companies continue to prioritize efficiency and sustainability, custom ceramic pellets are set to become an increasingly integral part of the manufacturing landscape, driving innovation and progress for years to come.

High-Quality Ceramic Vacuum Chuck for Enhanced Industrial Performance

St.Cera Co., Ltd. Unveils New Ceramic Vacuum Chuck for Precision ManufacturingSt.Cera Co., Ltd. has announced the launch of a new ceramic vacuum chuck, designed to meet the needs of precision manufacturing. The company, known for its expertise in precision ceramic manufacturing, has developed the vacuum chuck to cater to the growing demand for high-quality, reliable solutions in the industry.The ceramic vacuum chuck, which has been developed by a team of top-ranking experts and engineers at St.Cera Co., Ltd., is set to revolutionize the precision manufacturing sector. With a strong focus on research and development, manufacturing, and marketing of precision ceramic parts, the company has once again demonstrated its commitment to innovation and excellence.Speaking about the new product, a spokesperson for St.Cera Co., Ltd. said, "We are thrilled to introduce our latest innovation to the precision manufacturing industry. The ceramic vacuum chuck is a result of extensive research and development, aimed at providing our customers with a high-quality solution that meets their specific needs. We believe that this product will set new standards in precision manufacturing and offer unmatched performance and reliability."The ceramic vacuum chuck boasts a number of features that set it apart from other solutions currently available in the market. Its high-precision design ensures superior grip and stability, allowing for precise and efficient manufacturing processes. The vacuum chuck is also highly durable, thanks to its use of high-quality ceramics, and is designed to withstand the rigors of continuous use in demanding manufacturing environments.In addition to its exceptional performance, the ceramic vacuum chuck is also designed with ease of use in mind. Its user-friendly interface and intuitive controls make it simple to operate, enabling manufacturers to streamline their processes and improve overall productivity. This combination of cutting-edge technology and user-friendly design makes the vacuum chuck a valuable addition to any precision manufacturing operation.The launch of the ceramic vacuum chuck is a significant milestone for St.Cera Co., Ltd., further cementing the company's position as a leader in the precision ceramic manufacturing industry. With its strong focus on innovation and excellence, the company has established a reputation for delivering high-quality solutions that meet the evolving needs of its customers.As part of its commitment to customer satisfaction, St.Cera Co., Ltd. is offering comprehensive support and after-sales service for the ceramic vacuum chuck. This includes expert guidance on installation and operation, as well as ongoing maintenance and technical support to ensure that customers can maximize the potential of their investment.In conclusion, the launch of the ceramic vacuum chuck represents an exciting development for the precision manufacturing industry. With its advanced technology, superior performance, and user-friendly design, the vacuum chuck is set to make a significant impact on the sector, providing manufacturers with a reliable and efficient solution for their precision manufacturing needs. St.Cera Co., Ltd. continues to lead the way in precision ceramic manufacturing, and the introduction of the ceramic vacuum chuck is yet another testament to the company's commitment to innovation and excellence.

High-Quality Ceramic Finger for ESD Protection

St.Cera Co., Ltd. Introduces New ESd Ceramic Finger for Precision ApplicationsSt.Cera Co., Ltd. is proud to introduce its latest innovation in precision ceramic manufacturing - the ESd Ceramic Finger. As a private high-tech enterprise specializing in precision ceramic manufacturing, St.Cera Co., Ltd. has a team of top-ranking experts and engineers who have developed this cutting-edge product to meet the needs of a wide range of industries.The ESd Ceramic Finger is designed to provide precise and reliable performance in applications that require electrostatic discharge (ESd) protection. This innovative product addresses the growing demand for solutions that can effectively prevent damage to sensitive electronic components caused by static electricity.St.Cera Co., Ltd. has built its reputation on its core competencies in research and development, manufacturing, and marketing of precision ceramic parts. With the introduction of the ESd Ceramic Finger, the company is further cementing its position as a leader in the field of precision ceramic manufacturing.The ESd Ceramic Finger is an essential component in various industries such as electronics, semiconductor manufacturing, automotive, aerospace, and medical devices. Its advanced design and high-quality materials make it ideal for use in applications where static electricity poses a risk to the integrity of electronic components.The ESd Ceramic Finger is engineered to provide consistent electrostatic discharge protection, ensuring that sensitive electronic devices are safeguarded from potential damage. Its superior performance and durability make it a reliable solution for manufacturers and engineers seeking to improve the reliability and longevity of their products.St.Cera Co., Ltd. is committed to providing innovative solutions that meet the evolving needs of the industry. The ESd Ceramic Finger is a testament to the company's dedication to delivering high-quality products that address critical challenges faced by businesses today.In addition to the ESd Ceramic Finger, St.Cera Co., Ltd. offers a comprehensive range of precision ceramic parts that are designed to meet the stringent requirements of modern manufacturing processes. The company's expertise in precision ceramic manufacturing has enabled it to establish itself as a trusted partner for businesses seeking reliable and high-performance components.As the demand for precision ceramic parts continues to grow, St.Cera Co., Ltd. remains at the forefront of the industry, leveraging its extensive experience and technical know-how to develop innovative solutions that deliver exceptional value to its customers.The introduction of the ESd Ceramic Finger underscores St.Cera Co., Ltd.'s commitment to pushing the boundaries of precision ceramic manufacturing and providing cutting-edge solutions that empower businesses to achieve their operational goals.St.Cera Co., Ltd. is dedicated to maintaining its position as a leader in precision ceramic manufacturing, and the ESd Ceramic Finger is a testament to the company's ongoing efforts to deliver products that set new standards for performance and reliability.In conclusion, the introduction of the ESd Ceramic Finger by St.Cera Co., Ltd. represents a significant milestone for the company and the industry as a whole. This innovative product is poised to make a positive impact on a wide range of industries, offering enhanced electrostatic discharge protection and exceptional performance in precision applications. With its unwavering commitment to excellence, St.Cera Co., Ltd. is well-positioned to continue setting new benchmarks in precision ceramic manufacturing and supporting the evolving needs of its customers.

Durable and High-Quality Beryllia Ceramic Tube for Various Applications

St.Cera Co., Ltd., a private high-tech enterprise specializing in precision ceramic manufacturing, has recently announced the release of their latest product, the high-quality Beryllia Ceramic Tube. This new product is set to have a significant impact on various industries due to its excellent thermal conductivity, high strength, and resistance to corrosion.The Beryllia Ceramic Tube is manufactured using cutting-edge technology and top-quality materials, ensuring that it meets the highest standards of quality and performance. With a team of top-ranking experts and engineers in precision ceramic manufacturing, St.Cera Co., Ltd. has invested heavily in research and development to create a product that stands out in the market.The company's core competencies lie in the research and development, manufacturing, and marketing of precision ceramic parts. This has allowed them to create innovative products that meet the needs of their clients in various industries, including aerospace, electronics, and healthcare.The Beryllia Ceramic Tube is expected to have a significant impact on the aerospace industry due to its excellent thermal conductivity and high strength. These properties make it an ideal material for use in components that require high heat resistance and durability. Additionally, its resistance to corrosion makes it a reliable choice for applications in extreme environments.In the electronics industry, the Beryllia Ceramic Tube is set to become a game-changer due to its excellent thermal conductivity. This property allows for efficient heat dissipation, making it an ideal material for use in electronic components such as insulators and heat sinks. Its high strength also makes it a reliable choice for applications that require durability and reliability.The healthcare industry is also set to benefit from the Beryllia Ceramic Tube, as its resistance to corrosion makes it an ideal material for use in medical devices and equipment. Its high strength and durability ensure that it can withstand the rigors of medical use, making it a valuable addition to the industry."We are excited to introduce the high-quality Beryllia Ceramic Tube to the market," said a spokesperson for St.Cera Co., Ltd. "We have invested a significant amount of time and resources into the research and development of this product, and we believe that it will have a significant impact on various industries. We are confident that our clients will benefit from the excellent thermal conductivity, high strength, and resistance to corrosion that the Beryllia Ceramic Tube offers."St.Cera Co., Ltd. is committed to providing innovative solutions to their clients, and the release of the Beryllia Ceramic Tube is a testament to their dedication to excellence in precision ceramic manufacturing. With a strong focus on quality and performance, the company has positioned itself as a leader in the industry.As the demand for high-quality precision ceramic parts continues to grow, St.Cera Co., Ltd. is well-positioned to meet the needs of their clients with their innovative products and advanced manufacturing capabilities. The release of the Beryllia Ceramic Tube further solidifies the company's position as a key player in the precision ceramic manufacturing industry.With its excellent thermal conductivity, high strength, and resistance to corrosion, the high-quality Beryllia Ceramic Tube is set to become a valuable addition to various industries. St.Cera Co., Ltd.'s dedication to excellence in precision ceramic manufacturing ensures that their clients will benefit from the superior performance and reliability of their products.

Durable and Customizable Ceramic Edge Ring for Various Applications

Custom Ceramic Edge Ring Revolutionizes Industrial MachineryThe manufacturing industry is constantly evolving with the introduction of new technologies and materials that aim to improve efficiency and productivity. One such innovation is the custom ceramic edge ring, which has the potential to revolutionize industrial machinery.The custom ceramic edge ring is a breakthrough product developed by a leading manufacturer in the industry. The company, which has been at the forefront of ceramic engineering for over three decades, prides itself on its expertise in creating high-performance ceramic components for various industrial applications.The custom ceramic edge ring is a critical component in industrial machinery, particularly in applications where high-temperature resistance, wear resistance, and low friction are essential. The edge ring is typically used in manufacturing processes such as metal rolling, glass production, and semiconductor manufacturing, where it is subjected to extreme conditions and heavy wear.The innovative design of the custom ceramic edge ring sets it apart from traditional materials such as metal or plastic. The use of advanced ceramic materials provides superior performance in terms of wear resistance, thermal stability, and dimensional accuracy. This means that the custom ceramic edge ring can withstand the harsh conditions of industrial operations, leading to longer service life and reduced downtime for equipment maintenance.One of the most significant advantages of the custom ceramic edge ring is its ability to maintain its shape and surface finish even under high mechanical stress and extreme temperatures. This is crucial for ensuring consistent and high-quality output in manufacturing processes, as any deviation in the edge ring's dimensions or surface finish can result in defective products and costly rework.In addition to its superior mechanical properties, the custom ceramic edge ring also offers excellent chemical resistance, making it ideal for applications involving corrosive materials or harsh chemicals. This further extends the service life of the edge ring and reduces the need for frequent replacements, contributing to cost savings for industrial operations.Furthermore, the custom ceramic edge ring's low friction properties contribute to energy savings in machinery operations, as it reduces the need for excessive lubrication and reduces frictional heat generation. This not only improves the efficiency of the equipment but also reduces the risk of heat-related damage to surrounding components.The introduction of the custom ceramic edge ring marks a significant advancement in the field of industrial materials and has the potential to benefit a wide range of industries, including steel manufacturing, glass production, and semiconductor processing. By incorporating this innovative component into their machinery, industrial companies can improve the overall performance of their equipment and achieve a competitive edge in their respective markets.The company behind the custom ceramic edge ring has already received positive feedback from early adopters in the industry, who have reported significant improvements in equipment performance and reliability after integrating the edge ring into their machinery. This success has spurred the company to further expand its production capacity and develop custom solutions to meet the specific needs of different industrial applications.With its commitment to continuous innovation and excellence in ceramic engineering, the company is poised to lead the way in advancing industrial materials and contributing to the evolution of manufacturing processes. The custom ceramic edge ring is just one example of how the company's expertise and dedication to pushing the boundaries of ceramic technology are driving progress in the industry.In conclusion, the custom ceramic edge ring represents a game-changing innovation in the field of industrial materials and machinery. Its superior mechanical properties, thermal stability, and chemical resistance make it an ideal solution for a wide range of manufacturing applications. With the company's continued commitment to innovation and excellence, the custom ceramic edge ring is set to revolutionize industrial machinery and contribute to the advancement of the manufacturing industry as a whole.