Everything You Need to Know About Quartz Dowel Pins

By:Admin

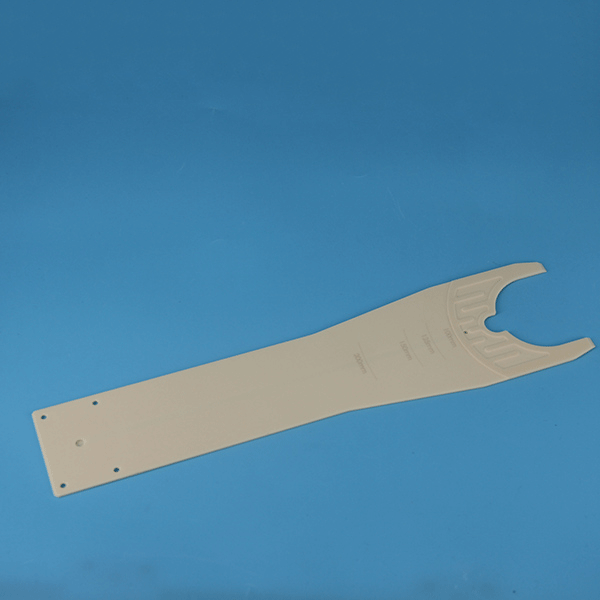

Shenzhen, China—As the demand for precision ceramic parts continues to grow, St. Cera Co., Ltd. is making a name for itself in the industry with its innovative quartz dowel pins. The private high-tech enterprise, specializing in precision ceramic manufacturing, has managed to combine its expertise in research and development, manufacturing, and marketing to create a product that has caught the attention of the market.

St. Cera Co., Ltd. is known for its top-ranking experts and engineers who are dedicated to pushing the boundaries of precision ceramic manufacturing. The company's commitment to excellence and innovation has solidified its position as a leader in the industry.

Quartz dowel pins are an essential component in many precision applications, and St. Cera Co., Ltd.'s product stands out for its exceptional quality and performance. The company's quartz dowel pins are designed to meet the highest standards of precision and reliability, making them the go-to choice for manufacturers in various industries.

One of the key factors driving the success of St. Cera Co., Ltd.'s quartz dowel pins is the superior materials used in their production. The company's precision ceramic experts have carefully selected high-quality quartz that meets the strictest specifications, ensuring that the dowel pins are strong, durable, and resistant to wear and tear.

Furthermore, St. Cera Co., Ltd. has invested heavily in state-of-the-art manufacturing technology to ensure that its quartz dowel pins are produced with the utmost precision and consistency. The company's advanced manufacturing processes guarantee that each dowel pin meets the exacting specifications required for its intended use.

In addition to the exceptional quality of its quartz dowel pins, St. Cera Co., Ltd. prides itself on its commitment to customer satisfaction. The company's dedicated team works closely with clients to understand their specific needs and requirements, ensuring that the quartz dowel pins meet and exceed expectations.

St. Cera Co., Ltd.'s quartz dowel pins have already made waves in the market, with a growing number of manufacturers turning to the company for their precision ceramic needs. The dowel pins have been particularly well-received in industries such as aerospace, automotive, electronics, and medical devices, where precision and reliability are paramount.

The success of St. Cera Co., Ltd.'s quartz dowel pins is a testament to the company's dedication to pushing the boundaries of precision ceramic manufacturing. By combining its expertise, state-of-the-art technology, and unwavering commitment to quality, the company has managed to set a new standard in the industry.

Looking ahead, St. Cera Co., Ltd. is poised to continue its upward trajectory, with plans to expand its product line and further solidify its position as a leader in precision ceramic manufacturing. With its innovative quartz dowel pins leading the way, the company is well-positioned to meet the evolving needs of the market and drive further growth and success in the years to come.

In conclusion, St. Cera Co., Ltd.'s quartz dowel pins have set a new standard in precision ceramic manufacturing, thanks to their exceptional quality, performance, and reliability. The company's unwavering commitment to excellence and innovation has solidified its position as a leader in the industry, and its dedication to customer satisfaction is setting it apart from the competition. As the demand for precision ceramic parts continues to grow, St. Cera Co., Ltd. is well-positioned to meet the needs of the market with its superior quartz dowel pins.

Company News & Blog

High-quality Ceramic Laser Nozzle for Precision Laser Cutting

Custom Ceramic Laser Nozzle Revolutionizes Precision ManufacturingPrecision manufacturing has always been at the forefront of technological innovation and advancement. As industries continue to demand higher levels of precision and quality, companies are constantly seeking innovative solutions to meet these requirements. One such solution comes in the form of custom ceramic laser nozzles, a game-changing technology that is set to revolutionize precision manufacturing.St.Cera Co., Ltd. is a private high-tech enterprise specializing in precision ceramic manufacturing. The company has a team of top-ranking experts and engineers in precision ceramic manufacturing. Their core competencies lie in research and development, manufacturing, and marketing of precision ceramic parts. With a strong emphasis on innovation, St.Cera Co., Ltd. has been at the forefront of developing cutting-edge solutions for precision manufacturing.The custom ceramic laser nozzle is the latest offering from St.Cera Co., Ltd. This innovative product is designed to meet the growing demands for precision and quality in manufacturing processes. The nozzle is made from high-quality ceramic material, which offers a number of advantages over traditional metal nozzles. The use of ceramic material allows for greater precision and control in laser cutting applications, resulting in higher quality finished products.One of the key benefits of the custom ceramic laser nozzle is its ability to withstand extreme temperatures and harsh working environments. This makes it an ideal choice for a wide range of manufacturing applications, including automotive, aerospace, and medical industries. The nozzle's durability and resistance to wear and tear ensure long-term reliability and performance, even in the most demanding of operating conditions.In addition to its superior durability, the custom ceramic laser nozzle also offers improved thermal conductivity, which is essential for maintaining stable and consistent laser cutting processes. This results in more accurate and precise cuts, leading to higher quality finished products. The nozzle's unique design also allows for better heat dissipation, reducing the risk of thermal damage to the workpiece and the surrounding equipment.Furthermore, the custom ceramic laser nozzle boasts excellent corrosion resistance, making it suitable for use with a wide variety of materials, including metals, plastics, and composites. This versatility makes it an invaluable tool for manufacturers looking to enhance their capabilities and expand their product offerings.St.Cera Co., Ltd. has leveraged its expertise in precision ceramic manufacturing to develop a product that is not only technologically advanced but also cost-effective. The company's commitment to quality and innovation ensures that the custom ceramic laser nozzle meets the highest industry standards and delivers exceptional performance to its users.As the demand for precision manufacturing continues to grow, the custom ceramic laser nozzle is poised to play a pivotal role in shaping the future of the industry. Its unique combination of durability, thermal conductivity, and corrosion resistance makes it an indispensable tool for manufacturers looking to enhance their capabilities and improve the quality of their products.In conclusion, St.Cera Co., Ltd.'s custom ceramic laser nozzle represents a significant advancement in precision manufacturing technology. Its innovative design and superior performance set a new standard for precision and quality in manufacturing processes. As industries continue to push the boundaries of what is possible, the custom ceramic laser nozzle stands ready to meet the evolving needs of modern manufacturing. With its unparalleled reliability and versatility, this groundbreaking technology is set to revolutionize precision manufacturing for years to come.

Durable Ceramic Bushes for Various Applications: A Comprehensive Guide

Ceramic Bush: Revolutionizing the Industry with Innovative SolutionsIn the world of industrial manufacturing, finding reliable and durable components is critical to the success of any business. This is where Ceramic Bush comes in. An industry leader in the production of high-quality ceramic components, Ceramic Bush has been providing innovative solutions to a wide range of industries for [xx] years. With a strong focus on research and development, the company has continuously pushed the boundaries of what is possible with ceramic materials, revolutionizing the industry in the process.Founded in [xx] by a team of passionate engineers and materials scientists, Ceramic Bush has quickly grown to become a trusted partner for businesses in need of high-performance ceramic components. The company's state-of-the-art manufacturing facilities and cutting-edge technology allow them to produce a wide range of products to meet the diverse needs of their customers. From ceramic bushings and insulators to custom-designed components, Ceramic Bush has the expertise and capabilities to deliver top-quality solutions.One of the key advantages of ceramic components is their exceptional durability and resistance to wear and tear. This makes them ideal for use in demanding industrial applications where traditional materials may not hold up. Ceramic Bush has harnessed this potential to develop a range of products that offer superior performance and longevity, helping their clients to improve the reliability and efficiency of their operations.In addition to their standard product offerings, Ceramic Bush also specializes in the development of custom solutions tailored to the specific needs of their customers. Their team of experienced engineers works closely with clients to understand their requirements and design bespoke ceramic components that meet their exact specifications. This collaborative approach has earned Ceramic Bush a reputation for delivering innovative and cost-effective solutions to even the most challenging engineering problems.Furthermore, the company is committed to sustainability and eco-friendly practices. Ceramic materials are inherently environmentally friendly, as they are non-toxic and non-reactive. In addition, Ceramic Bush has implemented a range of initiatives to minimize waste and reduce their environmental footprint, ensuring that their products are not only high-performance but also environmentally responsible.Ceramic Bush's dedication to research and development has also led to the continuous improvement of their products. By investing in new technologies and materials, the company has been able to stay at the forefront of ceramic component innovation, offering their clients the latest advancements in the field. This commitment to excellence has allowed Ceramic Bush to maintain its position as a leader in the industry and a preferred partner for businesses seeking reliable and high-performance ceramic components.The company's success can be attributed not only to its technical expertise but also to its unwavering commitment to customer satisfaction. By prioritizing the needs of their clients and providing exceptional service and support, Ceramic Bush has built long-lasting relationships with businesses across a wide range of industries. Their dedication to delivering quality products and exceeding customer expectations has made them a trusted name in the industry.Looking to the future, Ceramic Bush is poised to continue its trajectory of growth and innovation. With a focus on expanding their product offerings and reaching new markets, the company is well-positioned to further solidify its position as a leader in the industry. As technology advances and the demand for high-performance ceramic components continues to grow, Ceramic Bush is ready to meet the needs of their customers with cutting-edge solutions that push the boundaries of what is possible.In conclusion, Ceramic Bush stands as a shining example of innovation and excellence in the industrial manufacturing sector. With its dedication to research and development, commitment to customer satisfaction, and focus on sustainability, the company has carved out a niche as a trusted provider of high-quality ceramic components. As they continue to push the boundaries of what is possible with ceramic materials, Ceramic Bush is well-positioned to shape the future of the industry and provide solutions that meet the evolving needs of their customers.

High-Quality Alumina Ceramic Tubes: A Comprehensive Overview

St.Cera Co., Ltd. is making headlines with its high-quality alumina ceramic tubes, which have been gaining recognition for their exceptional performance and durability. The company is a private high-tech enterprise specializing in precision ceramic manufacturing and prides itself on its team of top-ranking experts and engineers in this field.Alumina ceramic tubes are widely used in various industries, such as electronics, automotive, and medical, due to their excellent thermal conductivity, high strength, and resistance to corrosion. St.Cera's alumina ceramic tubes are known for their exceptional quality and are a result of extensive research and development, manufacturing, and marketing efforts.The company's commitment to quality is evident in its rigorous production processes and strict quality control measures. St.Cera ensures that each alumina ceramic tube meets the highest standards and conforms to all industry certifications.St.Cera's alumina ceramic tubes are designed to withstand extreme temperatures, making them ideal for applications in high-temperature environments. They are also valued for their superior electrical insulation properties, making them essential components in electronics and semiconductor manufacturing.Another key feature of St.Cera's alumina ceramic tubes is their exceptional mechanical strength, which allows them to endure harsh operating conditions without compromising their performance. This makes them the preferred choice for applications requiring reliability and longevity.In addition to their physical properties, St.Cera's alumina ceramic tubes are also highly resistant to chemical corrosion, making them suitable for use in harsh chemical environments. This versatility has made them a popular choice across a wide range of industries.The company's commitment to innovation and continuous improvement has led to the development of alumina ceramic tubes that offer superior performance and reliability. St.Cera's dedication to research and development has enabled them to stay at the forefront of precision ceramic manufacturing, ensuring that their products consistently meet and exceed industry standards.St.Cera's alumina ceramic tubes have already garnered positive feedback from customers and industry experts alike. Their reputation for quality and performance has positioned them as a preferred supplier in the precision ceramic market.The company's extensive experience in precision ceramic manufacturing, coupled with its state-of-the-art facilities and cutting-edge technology, allows them to deliver high-quality alumina ceramic tubes that meet the diverse needs of their customers. Their proficiency in customizing solutions further enhances their ability to cater to specific requirements and ensure customer satisfaction.St.Cera's dedication to customer satisfaction extends beyond the quality of their products. The company prides itself on its responsive and professional customer service, ensuring that clients receive the support and assistance they need throughout the entire process, from inquiry to delivery.As St.Cera continues to make strides in the precision ceramic industry, their alumina ceramic tubes stand out as a testament to their expertise and dedication to excellence. The company's focus on quality, innovation, and customer satisfaction has positioned them as a leader in the market, and their high-quality alumina ceramic tubes are a reflection of their ongoing commitment to surpassing expectations.In conclusion, St.Cera Co., Ltd.'s high-quality alumina ceramic tubes have solidified the company's position as a leading supplier in the precision ceramic manufacturing industry. With their dedication to research, development, and customer satisfaction, St.Cera continues to set the standard for excellence in the production of alumina ceramic tubes.

Top Manufacturers of High-Quality Bernoulli Ceramic Fingers

St.Cera Co., Ltd. is a private high-tech enterprise specializing in precision ceramic manufacturing. The company has a team of top-ranking experts and engineers in precision ceramic manufacturing. Our core competencies lie in research and development, manufacturing, and marketing of precision ceramic parts. In the world of precision ceramic manufacturing, the name St.Cera Co., Ltd. is synonymous with quality and innovation. With a commitment to excellence and a dedication to staying on the cutting edge of technology, the company has earned a reputation as a leader in the industry. One area in which St.Cera Co., Ltd. has really made a name for itself is in the manufacturing of high-quality Bernoulli ceramic fingers. These precision parts are used in a wide range of industries, including semiconductor manufacturing, medical devices, aerospace, and more. One of the key attributes of Bernoulli ceramic fingers is their ability to provide an extremely stable and consistent airflow. This is crucial in many applications, as even the smallest variation in airflow can have a significant impact on the performance of a system. By using high-quality Bernoulli ceramic fingers, companies can ensure that they are getting the level of performance and reliability that they need. St.Cera Co., Ltd. has invested heavily in research and development to ensure that their Bernoulli ceramic fingers are of the highest quality. This includes using the latest technology and manufacturing techniques to create parts that are not only incredibly precise, but also incredibly durable. In fact, St.Cera Co., Ltd. is so confident in the quality of their Bernoulli ceramic fingers that they offer a comprehensive warranty on all of their products. This is a testament to the company's commitment to standing behind their work and ensuring that their customers are completely satisfied with their purchase. When it comes to precision ceramic manufacturing, few companies can match the expertise and dedication of St.Cera Co., Ltd. With a team of top-ranking experts and engineers, state-of-the-art technology, and a commitment to excellence, the company continues to set the standard for quality in the industry. One of the things that sets St.Cera Co., Ltd. apart from its competitors is its ability to work closely with customers to develop custom solutions that meet their specific needs. This includes everything from creating custom Bernoulli ceramic fingers to providing support and assistance throughout the entire process. As a private high-tech enterprise, St.Cera Co., Ltd. is also able to move quickly and adapt to changing market conditions. This means that the company is always at the forefront of the latest technological advancements and is able to offer its customers the most advanced solutions available. In summary, St.Cera Co., Ltd. is a leader in the precision ceramic manufacturing industry, and its high-quality Bernoulli ceramic fingers are a testament to the company's commitment to excellence. With a focus on innovation, quality, and customer satisfaction, the company continues to set the standard for what is possible in precision ceramic manufacturing.

High-Quality Ceramic Roller for Custom Applications

St.Cera Co., Ltd. Introduces Custom Beo Ceramic RollerSt.Cera Co., Ltd. is proud to introduce their latest innovation in precision ceramic manufacturing, the Custom Beo Ceramic Roller. This new product is the result of the company's commitment to research and development and their dedication to producing high-quality precision ceramic parts.As a private high-tech enterprise, St.Cera Co., Ltd. has established itself as a leader in the industry, with a team of top-ranking experts and engineers specializing in precision ceramic manufacturing. With their core competencies in research and development, manufacturing, and marketing of precision ceramic parts, the company has continuously pushed the boundaries of innovation in the field.The introduction of the Custom Beo Ceramic Roller marks another milestone for St.Cera Co., Ltd. as they continue to expand their product offerings and expertise in precision ceramic manufacturing. This new product is designed to meet the specific needs of their customers, providing a customized solution for various applications.The Custom Beo Ceramic Roller is a testament to St.Cera Co., Ltd.'s dedication to meeting the demands of their customers and delivering superior quality products. The roller is meticulously crafted using advanced ceramic materials, ensuring exceptional durability and performance in any application.One of the key features of the Custom Beo Ceramic Roller is its versatility. It can be customized to meet the exact specifications of a customer's application, making it suitable for a wide range of industries, including automotive, aerospace, electronics, and more. This flexibility allows St.Cera Co., Ltd. to cater to the diverse needs of their clientele and provide tailored solutions for their unique requirements.Furthermore, the Custom Beo Ceramic Roller offers superior performance compared to traditional rollers, thanks to the advanced ceramic materials used in its construction. Its high wear resistance and low friction properties make it an ideal choice for high-speed and high-temperature applications, where durability and reliability are essential.In addition to its exceptional performance, the Custom Beo Ceramic Roller also boasts a longer service life, reducing the need for frequent replacements and maintenance. This not only helps businesses save on costs but also minimizes downtime, leading to improved overall efficiency and productivity.St.Cera Co., Ltd. takes great pride in the development of the Custom Beo Ceramic Roller and is confident in its ability to meet the demands of the market. With their expertise in precision ceramic manufacturing, the company is well-equipped to cater to the needs of industries requiring high-performance components and solutions.The launch of the Custom Beo Ceramic Roller further solidifies St.Cera Co., Ltd.'s position as a leader in the precision ceramic manufacturing industry. Through continuous innovation and a commitment to excellence, the company has proven its ability to deliver cutting-edge solutions that meet the evolving needs of the market.To learn more about the Custom Beo Ceramic Roller and St.Cera Co., Ltd.'s precision ceramic manufacturing capabilities, interested parties can visit the company's website or contact their team directly for inquiries. St.Cera Co., Ltd. is dedicated to providing top-quality products and services, and the introduction of the Custom Beo Ceramic Roller is a testament to their unwavering commitment to innovation and customer satisfaction.In conclusion, the introduction of the Custom Beo Ceramic Roller by St.Cera Co., Ltd. represents a significant advancement in precision ceramic manufacturing. The company's expertise and dedication to excellence have resulted in a product that offers superior performance, durability, and versatility, catering to the diverse needs of various industries. With the launch of this innovative product, St.Cera Co., Ltd. continues to set new standards in the field of precision ceramic manufacturing, solidifying its reputation as a top-tier provider of high-quality ceramic solutions.

High-quality Ceramic End Effector for Custom Applications

St.Cera Co., Ltd. Unveils Custom Ceramic End Effector for Precision ManufacturingSt.Cera Co., Ltd. is proud to announce the launch of their latest innovation in precision ceramic manufacturing - the Custom Ceramic End Effector. With a team of top-ranking experts and engineers specializing in precision ceramic manufacturing, St.Cera Co., Ltd. has established itself as a leader in the industry, focusing on research, development, manufacturing, and marketing of precision ceramic parts.The Custom Ceramic End Effector is a game-changer in the field of precision manufacturing. It is designed to meet the specific needs of manufacturers who require precise, reliable, and durable end effectors for their production processes. The end effector is custom-engineered to provide the highest level of performance, ensuring seamless integration into existing manufacturing systems.Precision manufacturing requires tools and components that can withstand the rigors of high-speed, high-temperature, and high-pressure operations. This is where St.Cera Co., Ltd.'s Custom Ceramic End Effector shines. The end effector is crafted from high-quality, advanced ceramics that offer exceptional strength, durability, and resistance to wear and tear. Its unique composition allows for smooth, frictionless movement, ensuring optimal performance and longevity.The Custom Ceramic End Effector is designed to meet the diverse needs of various industries, including automotive, aerospace, electronics, medical devices, and many others. Its customizable design ensures that it can be tailored to specific production requirements, making it a versatile solution for manufacturers across different sectors.One of the key advantages of the Custom Ceramic End Effector is its ability to withstand extreme temperatures and corrosive environments. This makes it an ideal choice for applications that involve exposure to harsh conditions, such as high-heat welding, precision cutting, and chemical processing.Furthermore, the Custom Ceramic End Effector offers significant cost savings for manufacturers. Its long-lasting durability reduces the need for frequent replacements and maintenance, resulting in lower overall production costs and increased efficiency. Additionally, its precise and reliable performance contributes to improved product quality and consistency, leading to higher customer satisfaction."We are thrilled to introduce the Custom Ceramic End Effector to the market," said a spokesperson for St.Cera Co., Ltd. "Our team has worked tirelessly to develop a product that meets the exacting standards of precision manufacturing. We believe that this end effector will revolutionize the way manufacturers approach their production processes, offering a superior solution that delivers exceptional performance and value."St.Cera Co., Ltd. has a long-standing reputation for delivering high-quality precision ceramic parts to a global customer base. With a commitment to excellence, innovation, and customer satisfaction, the company has become a trusted partner for manufacturers seeking reliable and advanced solutions for their production needs.The launch of the Custom Ceramic End Effector further solidifies St.Cera Co., Ltd.'s position as a leader in the precision ceramic manufacturing industry. By offering a product that combines cutting-edge technology, superior performance, and cost-effectiveness, the company continues to demonstrate its dedication to meeting the evolving needs of the manufacturing sector.As the manufacturing industry continues to advance, the demand for precision components that can withstand the challenges of modern production processes will only increase. With the Custom Ceramic End Effector, St.Cera Co., Ltd. has set a new standard for excellence in precision manufacturing, providing a solution that empowers manufacturers to achieve superior results and drive their businesses forward.

Durable and High-Quality Ceramic Washers for Various Applications

High-Quality Ceramic Washer Revolutionizing Industry StandardsIn today's fast-paced world, industries are constantly seeking to improve their production processes to meet the ever-growing demand for quality products. One company that has been leading the charge in this regard is {}. With a focus on innovation, quality, and customer satisfaction, {} has been at the forefront of developing high-quality ceramic washers that are revolutionizing industry standards.{} has been in the business of manufacturing ceramic washers for over a decade, and their commitment to excellence has made them a trusted name in the industry. Their dedication to producing top-quality products has allowed them to build a reputation for reliability and efficiency.The company's high-quality ceramic washers are designed to meet the demanding needs of various industries, including automotive, aerospace, electronics, and medical devices. The superior strength, durability, and resistance to corrosion make these washers an ideal choice for critical applications where reliability is essential.The secret behind the exceptional performance of {}'s ceramic washers lies in their manufacturing process. Using advanced ceramic materials and state-of-the-art production techniques, the company ensures that each washer meets the highest standards of quality and precision. This attention to detail sets {} apart from their competitors and gives their customers the confidence that they are using the best products available in the market.Furthermore, {}'s commitment to sustainability is evident in their choice of materials and production processes. By using ceramic, a highly durable and eco-friendly material, the company is contributing to the reduction of environmental impact. Additionally, their efficient manufacturing processes minimize waste and energy consumption, further cementing their position as a responsible and forward-thinking company.The impact of {}'s high-quality ceramic washers goes beyond the products themselves. By providing reliable and long-lasting components, {} is helping their clients improve their operational efficiency and reduce maintenance costs. This has a ripple effect throughout the industries they serve, leading to improved productivity and ultimately contributing to the overall success of their customers' businesses.In addition to their commitment to product quality, {} places great emphasis on customer satisfaction. Their team of dedicated professionals works closely with clients to understand their specific requirements and provide customized solutions. This collaborative approach ensures that each customer receives the best products for their unique needs, setting {} apart as a company that truly cares about the success of their clients.Looking ahead, {} is continuously striving to push the boundaries of innovation in ceramic washer technology. By investing in research and development, they are constantly exploring new materials, processes, and applications to further improve their products and stay ahead of industry trends. This forward-thinking approach ensures that {} remains at the forefront of the industry, providing their customers with cutting-edge solutions that meet the evolving demands of the market.With a strong focus on quality, innovation, and customer satisfaction, {} continues to set new standards in the industry with their high-quality ceramic washers. Their dedication to excellence, commitment to sustainability, and forward-thinking approach position them as a trusted partner for businesses across a wide range of industries. As they continue to innovate and push the boundaries of what's possible, {} is poised to remain a leader in the industry for years to come.

Durable and Stylish Zirconia Ceramic Fork: A Must-Have for Your Kitchen

St.Cera Co., Ltd., a private high-tech enterprise specializing in precision ceramic manufacturing, has recently unveiled its latest product, the Custom Zirconiaceramic Fork. This innovative new product is set to revolutionize the world of kitchen utensils with its durability and cutting-edge design.The Custom Zirconiaceramic Fork is manufactured using advanced precision ceramic technology, which ensures exceptional strength and durability. This makes the fork highly resistant to wear and corrosion, making it an ideal choice for everyday use in the kitchen. The superior strength of the ceramic material also means that the fork is less likely to bend or break, providing a reliable and long-lasting utensil for consumers.The company's team of top-ranking experts and engineers in precision ceramic manufacturing have worked tirelessly to develop the Custom Zirconiaceramic Fork, ensuring that it meets the highest standards of quality and performance. The fork is not only durable, but also lightweight and easy to handle, making it a practical and convenient choice for consumers.In addition to its impressive durability, the Custom Zirconiaceramic Fork also boasts a sleek and modern design that is sure to appeal to consumers. The fork is available in a range of stylish colors, allowing consumers to add a touch of sophistication to their kitchen utensils. The attractive design, coupled with the fork's exceptional performance, is set to make it a popular choice for discerning consumers.St.Cera Co., Ltd. is known for its expertise in research and development, manufacturing, and marketing of precision ceramic parts. The company's commitment to excellence and innovation is evident in the Custom Zirconiaceramic Fork, which represents the latest advancement in precision ceramic technology. The company's dedication to quality and performance is reflected in every aspect of the fork, from its design to its manufacturing process.The launch of the Custom Zirconiaceramic Fork underscores St.Cera Co., Ltd.'s position as a leader in the precision ceramic manufacturing industry. The company's unwavering commitment to excellence has driven it to continuously push the boundaries of innovation, resulting in products that are at the forefront of technological advancement. The Custom Zirconiaceramic Fork is a testament to the company's dedication to providing consumers with the highest quality products that deliver exceptional performance.The launch of the Custom Zirconiaceramic Fork is set to create a buzz in the kitchen utensils market, with consumers eagerly anticipating the opportunity to experience the benefits of this cutting-edge product. With its unparalleled durability, modern design, and superior performance, the fork is expected to become a staple in kitchens around the world.St.Cera Co., Ltd. is confident that the Custom Zirconiaceramic Fork will be well-received by consumers, and the company is committed to ensuring that it is readily available to meet the demand. The company has already begun distribution of the fork, making it accessible to consumers who are eager to experience the benefits of this innovative product.In conclusion, the launch of the Custom Zirconiaceramic Fork is a significant milestone for St.Cera Co., Ltd., and it reinforces the company's position as a leader in precision ceramic manufacturing. The fork's exceptional durability, modern design, and superior performance make it a standout choice for consumers in search of high-quality kitchen utensils. As St.Cera Co., Ltd. continues to push the boundaries of innovation, consumers can look forward to more groundbreaking products that set new standards for excellence in the precision ceramic industry.

Durable Ceramic End Effector with High-Quality ESD Coating

St.Cera Co., Ltd., a private high-tech enterprise specializing in precision ceramic manufacturing, has recently announced the release of a high-quality Esd coating ceramic end effector. This new product is expected to make a significant impact in the industry due to its advanced features and superior performance.The company, based in [Location], has made a name for itself as a leader in precision ceramic manufacturing. With a team of top-ranking experts and engineers, St.Cera Co., Ltd. focuses on research and development, manufacturing, and marketing of precision ceramic parts. Their dedication to quality and innovation has established them as a trusted partner for businesses in a wide range of industries.The high-quality Esd coating ceramic end effector is the latest addition to St.Cera Co., Ltd.'s product line. This innovative product is designed to meet the demanding requirements of modern manufacturing processes, providing exceptional durability and reliability. The Esd coating allows for electrostatic discharge protection, making it an ideal solution for industries that require safeguarding against damage from static electricity.One of the key features of the new end effector is its high precision, which is essential for achieving accurate and consistent results in manufacturing processes. The precise control offered by this product is expected to improve overall efficiency and quality in various industrial applications.In addition to its precision, the high-quality Esd coating ceramic end effector offers exceptional wear resistance, ensuring a long service life even in the most demanding operating conditions. This durability is a result of St.Cera Co., Ltd.'s commitment to using the highest quality materials and manufacturing techniques in their products.The release of the high-quality Esd coating ceramic end effector further demonstrates St.Cera Co., Ltd.'s dedication to meeting the evolving needs of their customers. By continuously investing in research and development, the company is able to stay ahead of industry trends and deliver cutting-edge solutions that address the challenges faced by modern manufacturers."We are thrilled to introduce our latest innovation, the high-quality Esd coating ceramic end effector," said [Name], [Title] of St.Cera Co., Ltd. "This product represents the culmination of our expertise and commitment to excellence in precision ceramic manufacturing. We are confident that it will provide significant benefits to our customers and contribute to the continued success of their operations."The high-quality Esd coating ceramic end effector is now available for order from St.Cera Co., Ltd. and is expected to generate significant interest from businesses seeking to enhance their manufacturing processes. With its advanced features and superior performance, this product is poised to set a new standard for precision ceramic components in the industry.As St.Cera Co., Ltd. continues to expand its product offerings and strengthen its position as a leading provider of precision ceramic parts, the company remains focused on delivering the highest level of quality and value to its customers. With a proven track record of success and a commitment to innovation, St.Cera Co., Ltd. is well-equipped to meet the evolving needs of modern industries and drive positive change through its cutting-edge solutions.Overall, the release of the high-quality Esd coating ceramic end effector represents an important milestone for St.Cera Co., Ltd. and reinforces the company's reputation as an innovator in precision ceramic manufacturing. With its advanced features and exceptional performance, this product is expected to make a significant impact in the industry and provide new opportunities for businesses to improve their manufacturing processes.

High-quality Si3n4 Ceramic Dowel Pin for Custom Applications

Custom Si3n4 Ceramic Dowel PinInnovative Solution for Precision ManufacturingIn the world of precision manufacturing, every detail matters. From the design phase to the final product, each component plays a crucial role in ensuring the quality and performance of the end product. This is where custom ceramic dowel pins come into play, offering an innovative solution for manufacturers seeking to elevate their precision manufacturing processes.One company that is making waves in this space is {}. With a strong focus on pushing the boundaries of ceramic material technology, they have developed a custom Si3n4 ceramic dowel pin that is redefining precision manufacturing standards.The Si3n4 ceramic material used in these custom dowel pins exhibits exceptional properties that make it an ideal choice for precision applications. It offers high strength, hardness, and thermal stability, making it suitable for use in high-temperature and high-stress environments. Additionally, its low thermal conductivity and excellent wear resistance make it a reliable choice for applications where consistent performance is paramount.By leveraging their expertise in ceramic material science and precision engineering, {} has been able to create custom Si3n4 ceramic dowel pins that exceed industry standards. These custom pins are carefully designed and manufactured to meet the specific requirements of their clients, ensuring a precise fit and reliable performance in their manufacturing processes.One of the key advantages of using custom ceramic dowel pins is their exceptional dimensional stability. Traditional metal dowel pins are susceptible to wear and deformation over time, leading to inconsistencies in the manufacturing process. In contrast, custom ceramic dowel pins offer unparalleled dimensional stability, ensuring that the precision and accuracy of the manufacturing process are maintained over extended periods.The use of custom ceramic dowel pins also contributes to improved efficiency and cost savings in precision manufacturing. Their high resistance to wear and corrosion reduces the need for frequent replacements, resulting in lower maintenance costs and downtime. Additionally, the exceptional thermal stability of ceramic materials allows for higher operating temperatures, expanding the range of applications where these custom pins can be used.In addition to their superior mechanical and thermal properties, custom Si3n4 ceramic dowel pins offer excellent electrical insulation. This makes them an ideal choice for applications where electrical conductivity needs to be minimized, helping to prevent electrical interference and ensuring the reliability of the final product.As industries continue to push for higher precision and performance in their manufacturing processes, the demand for custom ceramic dowel pins is on the rise. Manufacturers across a wide range of industries, including aerospace, automotive, and medical devices, are turning to custom ceramic dowel pins to achieve greater precision, reliability, and efficiency in their production processes.With their expertise in ceramic material technology and precision engineering, {} is well-positioned to meet this growing demand. Their custom Si3n4 ceramic dowel pins are a testament to their commitment to pushing the boundaries of what is possible in precision manufacturing, and they continue to explore new and innovative solutions to meet the evolving needs of their clients.In conclusion, custom Si3n4 ceramic dowel pins are revolutionizing precision manufacturing by offering superior mechanical, thermal, and electrical properties. As the demand for higher precision and reliability continues to grow across industries, custom ceramic dowel pins are becoming an essential component in the quest for excellence in manufacturing processes. With their cutting-edge custom ceramic dowel pins, {} is at the forefront of this revolution, pushing the boundaries of ceramic material technology to deliver innovative solutions for precision manufacturing.