1. About price: The price is negotiable. It can be changed according to your quantity or package. 2. About MOQ: We can adjust it according to your requirement. 3. High quality: Using high quality material and establishing a strict quality control system, assigning specific persons in charge of each process of production, from raw material purchase to pack. 4. We offer the best service as we have. Experienced sales team are already to work for you. 5. How can we guarantee quality? Always 100% Inspection before shipment; 6. What certification you have? We are ISO 9001 Quality Management System Certificated company. 7. What services can we provide? Accepted Delivery Terms: FOB,EXW; Accepted Payment Currency: USD, CNY; Accepted Payment Type: T/T Language Spoken: English, Chinese 8. What is your delivery time? A: Normally, our delivery time is within 30 days after confirmation. 9. There are so many suppliers, why choose you as our business partner? We focus on ceramic parts manufacturing for over 15years, that is to say we also have accumulated 15years OEM experience.ble to grip and transport a warped wafer securely. Free from contact with the wafer except a periphery, so it won't leave grip marks and give uneven stress. Minimized contact area within 3mm periphery made the surface less likely to cause particles. Due to built-in air channel in a single piece body with no adhesives and metal cover, the structure becomes more durable and chemically stable under heated environments.

1. About price: The price is negotiable. It can be changed according to your quantity or package. 2. About MOQ: We can adjust it according to your requirement. 3. High quality: Using high quality material and establishing a strict quality control system, assigning specific persons in charge of each process of production, from raw material purchase to pack. 4. We offer the best service as we have. Experienced sales team are already to work for you. 5. How can we guarantee quality? Always 100% Inspection before shipment; 6. What certification you have? We are ISO 9001 Quality Management System Certificated company. 7. What services can we provide? Accepted Delivery Terms: FOB,EXW; Accepted Payment Currency: USD, CNY; Accepted Payment Type: T/T Language Spoken: English, Chinese 8. What is your delivery time? A: Normally, our delivery time is within 30 days after confirmation. 9. There are so many suppliers, why choose you as our business partner? We focus on ceramic parts manufacturing for over 15years, that is to say we also have accumulated 15years OEM experience.ble to grip and transport a warped wafer securely. Free from contact with the wafer except a periphery, so it won't leave grip marks and give uneven stress. Minimized contact area within 3mm periphery made the surface less likely to cause particles. Due to built-in air channel in a single piece body with no adhesives and metal cover, the structure becomes more durable and chemically stable under heated environments.ST.CERA Customized Alumina Ceramic Bernoulli end effector

ST.CERA offers customized alumina ceramic Bernoulli end effectors. As a factory, we specialize in precision ceramic components for various industries.

Request a QuotePRODUCTS DETAILS

1. About price: The price is negotiable. It can be changed according to your quantity or package. 2. About MOQ: We can adjust it according to your requirement. 3. High quality: Using high quality material and establishing a strict quality control system, assigning specific persons in charge of each process of production, from raw material purchase to pack. 4. We offer the best service as we have. Experienced sales team are already to work for you. 5. How can we guarantee quality? Always 100% Inspection before shipment; 6. What certification you have? We are ISO 9001 Quality Management System Certificated company. 7. What services can we provide? Accepted Delivery Terms: FOB,EXW; Accepted Payment Currency: USD, CNY; Accepted Payment Type: T/T Language Spoken: English, Chinese 8. What is your delivery time? A: Normally, our delivery time is within 30 days after confirmation. 9. There are so many suppliers, why choose you as our business partner? We focus on ceramic parts manufacturing for over 15years, that is to say we also have accumulated 15years OEM experience.ble to grip and transport a warped wafer securely. Free from contact with the wafer except a periphery, so it won't leave grip marks and give uneven stress. Minimized contact area within 3mm periphery made the surface less likely to cause particles. Due to built-in air channel in a single piece body with no adhesives and metal cover, the structure becomes more durable and chemically stable under heated environments.

1. About price: The price is negotiable. It can be changed according to your quantity or package. 2. About MOQ: We can adjust it according to your requirement. 3. High quality: Using high quality material and establishing a strict quality control system, assigning specific persons in charge of each process of production, from raw material purchase to pack. 4. We offer the best service as we have. Experienced sales team are already to work for you. 5. How can we guarantee quality? Always 100% Inspection before shipment; 6. What certification you have? We are ISO 9001 Quality Management System Certificated company. 7. What services can we provide? Accepted Delivery Terms: FOB,EXW; Accepted Payment Currency: USD, CNY; Accepted Payment Type: T/T Language Spoken: English, Chinese 8. What is your delivery time? A: Normally, our delivery time is within 30 days after confirmation. 9. There are so many suppliers, why choose you as our business partner? We focus on ceramic parts manufacturing for over 15years, that is to say we also have accumulated 15years OEM experience.ble to grip and transport a warped wafer securely. Free from contact with the wafer except a periphery, so it won't leave grip marks and give uneven stress. Minimized contact area within 3mm periphery made the surface less likely to cause particles. Due to built-in air channel in a single piece body with no adhesives and metal cover, the structure becomes more durable and chemically stable under heated environments.Hot Products

ST.CERA Customized 99.5% Alumina Ceramic parts

ST.CERA Customized semiconductor equipment Ceramic chucks

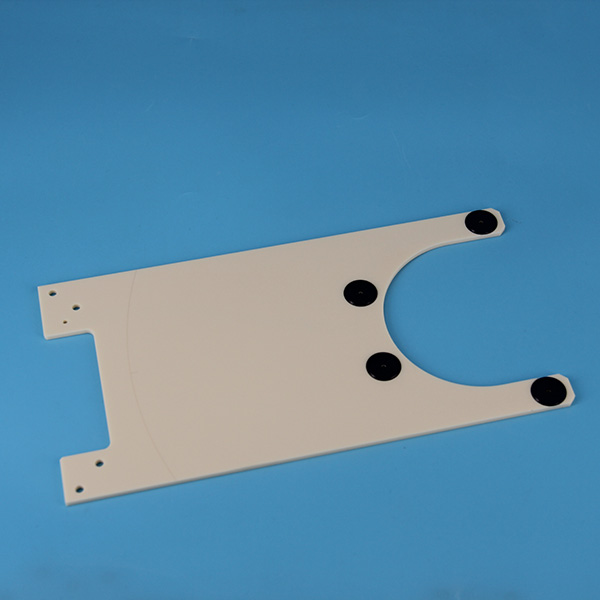

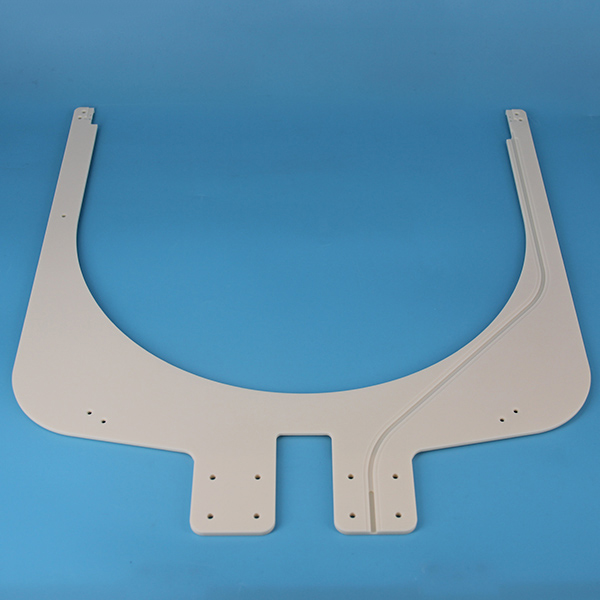

ST.CERA Customized Alumina Ceramic tray end effector

ST.CERA Customized 99.5% Alumina Ceramic tube

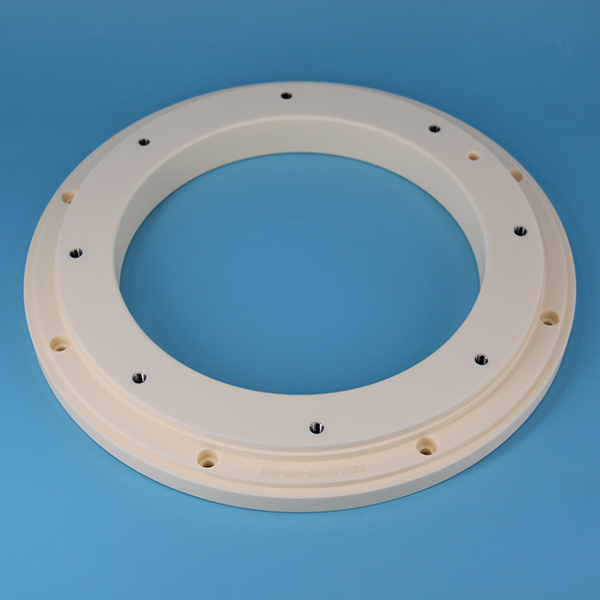

ST.CERA Customized semiconductor Ceramic focus ring

ST.CERA Customized 99.5% zirconia Ceramic rod ceramic pin

ST.CERA Customized AlN ceramic plates ceramic parts

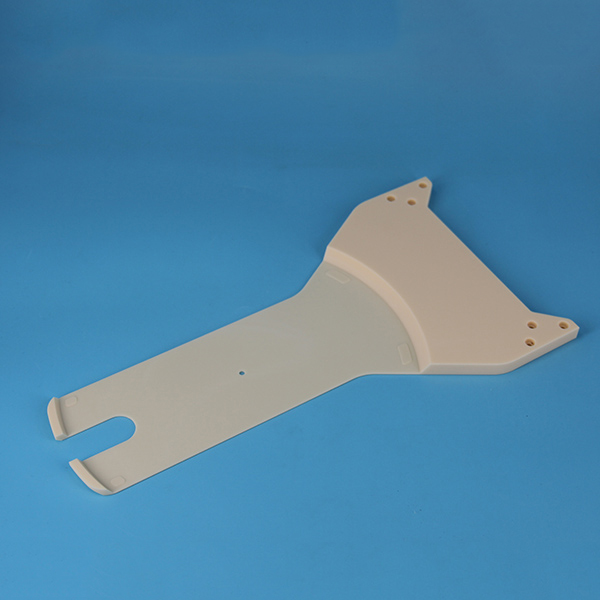

ST.CERA Customized Alumina Ceramic gripping end effector

ST.CERA Customized ESD Ceramic end effector

ST.CERA Customized semiconductor Ceramic bushing

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours