1. A complete set of our own team to support your project. We have outstanding R&D team, strict QC team, exquisite technology team and good service sales team to offer our customer the best service and products. We are both manufacturer and trading company. 2. We have our own factories and have formed a professional production system from material supplying and manufacture to sale, as well as a professional R&D and QC team. We always keep ourselves updated with market trends. We are ready to introduce new technology and service to meet the market needs. 3. Good price. We have our own factory, and will provide the best price for customers.It is possible to make mounting holes in any position to the length direction.1. How to apply for free samples? lf the item(you selected) itself have stock with lower value, we can send you some for testing, but we need your comments after tests. 2. What about the charge of samples? lf the item (you selected) itself have no stock or with higher value, usually double its fees.1. How long is your production lead time? It depends on product and order qty. Normally, it takes us 25 days for an order with MOQ qty. 2. When can I get the quotation? We usually quote you within 24 hours after we get your inquiry. If you are very urgent to get the quotation, please call us or tell us in your mail, so that we could regard your inquiry priority. 3.Can you send products to my country? Sure, we can. If you have no your own ship forwarder, we can help you.

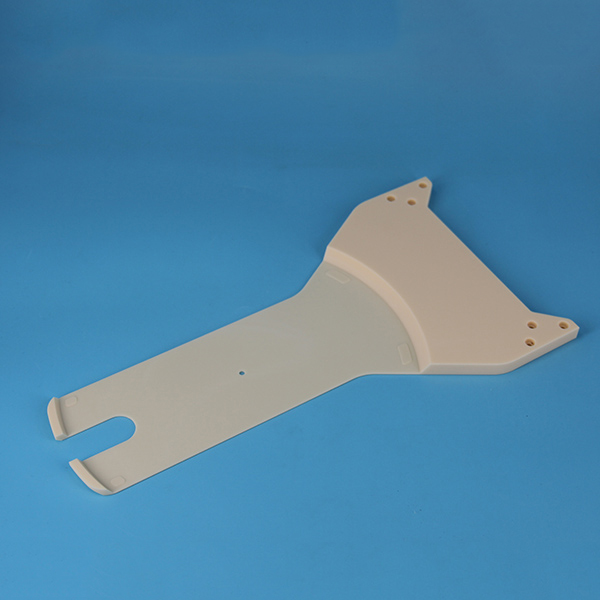

1. A complete set of our own team to support your project. We have outstanding R&D team, strict QC team, exquisite technology team and good service sales team to offer our customer the best service and products. We are both manufacturer and trading company. 2. We have our own factories and have formed a professional production system from material supplying and manufacture to sale, as well as a professional R&D and QC team. We always keep ourselves updated with market trends. We are ready to introduce new technology and service to meet the market needs. 3. Good price. We have our own factory, and will provide the best price for customers.It is possible to make mounting holes in any position to the length direction.1. How to apply for free samples? lf the item(you selected) itself have stock with lower value, we can send you some for testing, but we need your comments after tests. 2. What about the charge of samples? lf the item (you selected) itself have no stock or with higher value, usually double its fees.1. How long is your production lead time? It depends on product and order qty. Normally, it takes us 25 days for an order with MOQ qty. 2. When can I get the quotation? We usually quote you within 24 hours after we get your inquiry. If you are very urgent to get the quotation, please call us or tell us in your mail, so that we could regard your inquiry priority. 3.Can you send products to my country? Sure, we can. If you have no your own ship forwarder, we can help you.ST.CERA Customized Alumina Ceramic tray end effector

Get a custom alumina ceramic tray end effector from ST.CERA. As a factory, we offer high-quality, customized solutions for your industrial needs.

Request a QuotePRODUCTS DETAILS

1. A complete set of our own team to support your project. We have outstanding R&D team, strict QC team, exquisite technology team and good service sales team to offer our customer the best service and products. We are both manufacturer and trading company. 2. We have our own factories and have formed a professional production system from material supplying and manufacture to sale, as well as a professional R&D and QC team. We always keep ourselves updated with market trends. We are ready to introduce new technology and service to meet the market needs. 3. Good price. We have our own factory, and will provide the best price for customers.It is possible to make mounting holes in any position to the length direction.1. How to apply for free samples? lf the item(you selected) itself have stock with lower value, we can send you some for testing, but we need your comments after tests. 2. What about the charge of samples? lf the item (you selected) itself have no stock or with higher value, usually double its fees.1. How long is your production lead time? It depends on product and order qty. Normally, it takes us 25 days for an order with MOQ qty. 2. When can I get the quotation? We usually quote you within 24 hours after we get your inquiry. If you are very urgent to get the quotation, please call us or tell us in your mail, so that we could regard your inquiry priority. 3.Can you send products to my country? Sure, we can. If you have no your own ship forwarder, we can help you.

1. A complete set of our own team to support your project. We have outstanding R&D team, strict QC team, exquisite technology team and good service sales team to offer our customer the best service and products. We are both manufacturer and trading company. 2. We have our own factories and have formed a professional production system from material supplying and manufacture to sale, as well as a professional R&D and QC team. We always keep ourselves updated with market trends. We are ready to introduce new technology and service to meet the market needs. 3. Good price. We have our own factory, and will provide the best price for customers.It is possible to make mounting holes in any position to the length direction.1. How to apply for free samples? lf the item(you selected) itself have stock with lower value, we can send you some for testing, but we need your comments after tests. 2. What about the charge of samples? lf the item (you selected) itself have no stock or with higher value, usually double its fees.1. How long is your production lead time? It depends on product and order qty. Normally, it takes us 25 days for an order with MOQ qty. 2. When can I get the quotation? We usually quote you within 24 hours after we get your inquiry. If you are very urgent to get the quotation, please call us or tell us in your mail, so that we could regard your inquiry priority. 3.Can you send products to my country? Sure, we can. If you have no your own ship forwarder, we can help you.Hot Products

ST.CERA Customized 99.5% Alumina Ceramic rod

ST.CERA Customized Zirconia Ceramic tube

ST.CERA Customized Alumina Ceramic tray end effector

ST.CERA Customized semiconductor equipment Ceramic plate

ST.CERA Customized semiconductor equipment Ceramic chucks

ST.CERA Customized 99.5% Alumina Ceramic tube

ST.CERA Customized 99.5% Alumina Ceramic Loader Arm

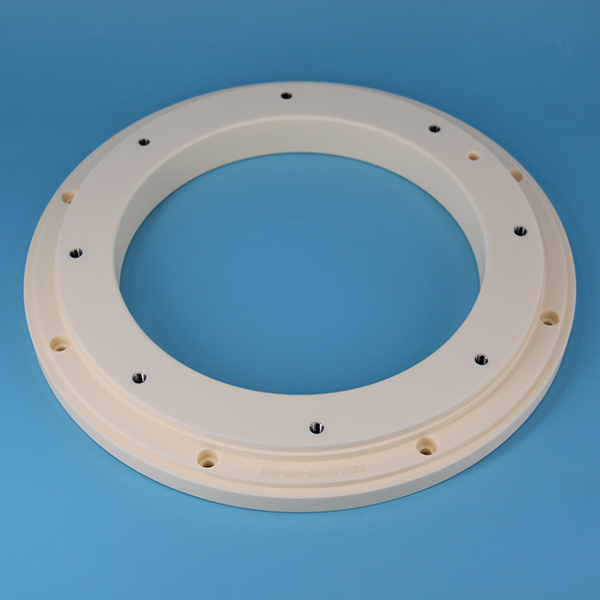

ST.CERA Customized semiconductor Ceramic focus ring

ST.CERA Customized 99.5% zirconia Ceramic rod ceramic pin

ST.CERA Customized AlN ceramic plates ceramic parts

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours