Professional online service team, any mail or message will reply within 24 hours. We have a strong team provide wholehearted service to customer at any time. We insist on Customer is Supreme, Staff toward Happiness. Put the Quality as the first consideration; OEM parts are acceptable. Advanced production equipment, strict quality testing and control system to make sure superior quality. Competitive price: we are a professional ceramic parts manufacturer in China, there is no middleman's profit, and you can get the most competitive price from us. Good quality: good quality can be guaranteed, it will help you keep the market share well. Fast delivery time: we have our own factory and professional manufacturer, which save your time to discuss with trading companies. We will try our best to meet your request.Prevent the particles that can generate from the bevel or angled edges and the back surface while wafers are transported or being in contact with End Effector / Handling Arm. For the guides, adopted a soft material that does not damage the wafer. Thinning is possible with ST.CERA's built-in vacuum channel technology that does not use adhesives. Possible to make mounting holes and to change the length and width of the base where the End Effector / Handling Arm is mounted on the robot. Mounting sensors, screws and brackets is available as an option. Designed to be used in atmosphere.

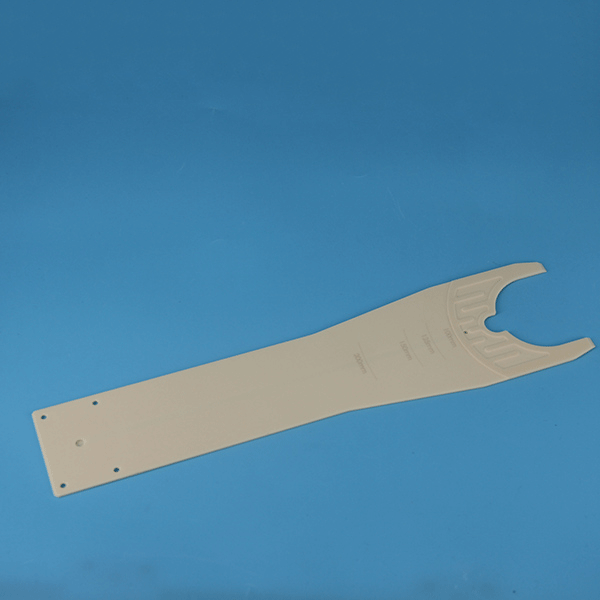

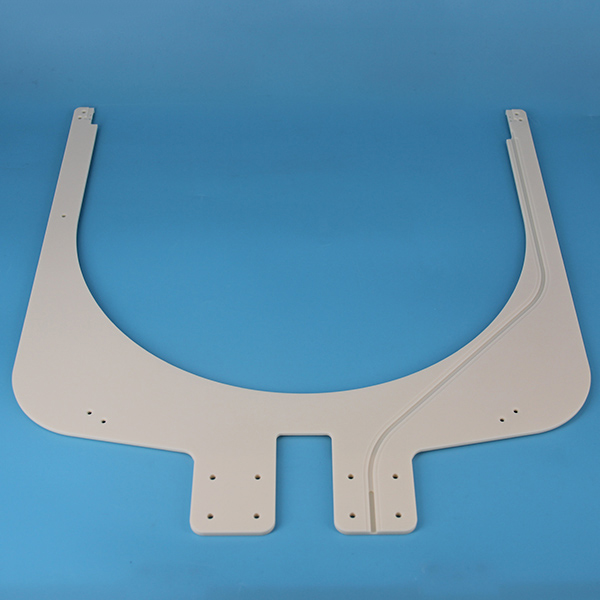

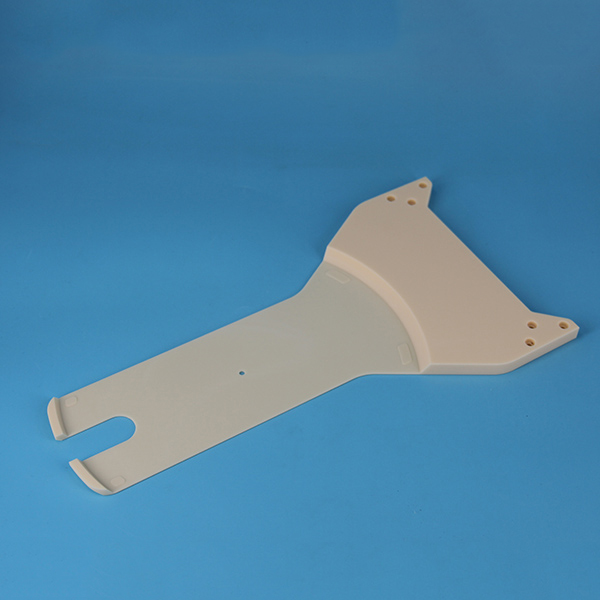

Professional online service team, any mail or message will reply within 24 hours. We have a strong team provide wholehearted service to customer at any time. We insist on Customer is Supreme, Staff toward Happiness. Put the Quality as the first consideration; OEM parts are acceptable. Advanced production equipment, strict quality testing and control system to make sure superior quality. Competitive price: we are a professional ceramic parts manufacturer in China, there is no middleman's profit, and you can get the most competitive price from us. Good quality: good quality can be guaranteed, it will help you keep the market share well. Fast delivery time: we have our own factory and professional manufacturer, which save your time to discuss with trading companies. We will try our best to meet your request.Prevent the particles that can generate from the bevel or angled edges and the back surface while wafers are transported or being in contact with End Effector / Handling Arm. For the guides, adopted a soft material that does not damage the wafer. Thinning is possible with ST.CERA's built-in vacuum channel technology that does not use adhesives. Possible to make mounting holes and to change the length and width of the base where the End Effector / Handling Arm is mounted on the robot. Mounting sensors, screws and brackets is available as an option. Designed to be used in atmosphere.ST.CERA Customized Alumina Ceramic vacuum end effector

ST.CERA offers customized Alumina Ceramic vacuum end effectors. As a factory, we provide high-quality, durable solutions for all your vacuum handling needs.

Request a QuotePRODUCTS DETAILS

Professional online service team, any mail or message will reply within 24 hours. We have a strong team provide wholehearted service to customer at any time. We insist on Customer is Supreme, Staff toward Happiness. Put the Quality as the first consideration; OEM parts are acceptable. Advanced production equipment, strict quality testing and control system to make sure superior quality. Competitive price: we are a professional ceramic parts manufacturer in China, there is no middleman's profit, and you can get the most competitive price from us. Good quality: good quality can be guaranteed, it will help you keep the market share well. Fast delivery time: we have our own factory and professional manufacturer, which save your time to discuss with trading companies. We will try our best to meet your request.Prevent the particles that can generate from the bevel or angled edges and the back surface while wafers are transported or being in contact with End Effector / Handling Arm. For the guides, adopted a soft material that does not damage the wafer. Thinning is possible with ST.CERA's built-in vacuum channel technology that does not use adhesives. Possible to make mounting holes and to change the length and width of the base where the End Effector / Handling Arm is mounted on the robot. Mounting sensors, screws and brackets is available as an option. Designed to be used in atmosphere.

Professional online service team, any mail or message will reply within 24 hours. We have a strong team provide wholehearted service to customer at any time. We insist on Customer is Supreme, Staff toward Happiness. Put the Quality as the first consideration; OEM parts are acceptable. Advanced production equipment, strict quality testing and control system to make sure superior quality. Competitive price: we are a professional ceramic parts manufacturer in China, there is no middleman's profit, and you can get the most competitive price from us. Good quality: good quality can be guaranteed, it will help you keep the market share well. Fast delivery time: we have our own factory and professional manufacturer, which save your time to discuss with trading companies. We will try our best to meet your request.Prevent the particles that can generate from the bevel or angled edges and the back surface while wafers are transported or being in contact with End Effector / Handling Arm. For the guides, adopted a soft material that does not damage the wafer. Thinning is possible with ST.CERA's built-in vacuum channel technology that does not use adhesives. Possible to make mounting holes and to change the length and width of the base where the End Effector / Handling Arm is mounted on the robot. Mounting sensors, screws and brackets is available as an option. Designed to be used in atmosphere.Hot Products

ST.CERA Customized semiconductor equipment Ceramic plate

ST.CERA Customized AlN ceramic plates ceramic parts

ST.CERA Customized Alumina Ceramic gripping end effector

ST.CERA Customized Alumina Ceramic tray end effector

ST.CERA Customized semiconductor equipment Ceramic chucks

ST.CERA Customized Zirconia Ceramic tube

ST.CERA Customized ESD Ceramic end effector

ST.CERA Customized 99.5% Alumina Ceramic tube

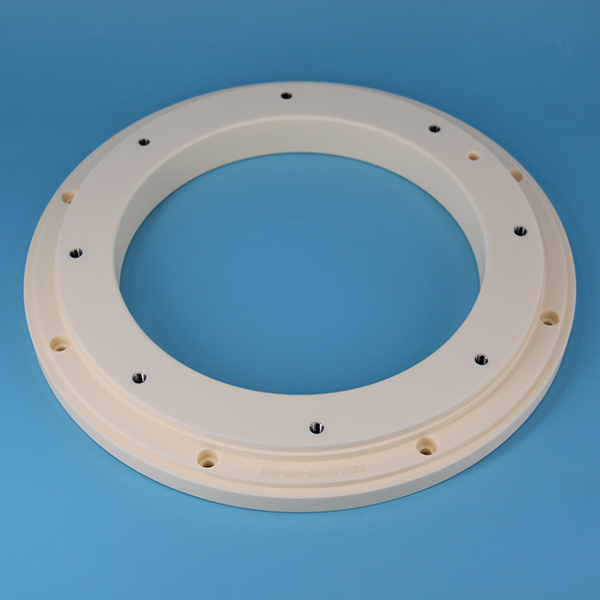

ST.CERA Customized semiconductor Ceramic focus ring

ST.CERA Customized semiconductor Ceramic bushing

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours